Two trends are shaping demand for controlled expansion alloys like 4J42. First, semiconductor packages are getting denser and more diverse — optical packages, MEMS sensors, and high-power modules now demand hermetic seals at smaller scales. That drives tighter tolerances on CTE and flatness. Second, test and qualification cycles have become more aggressive: more thermal cycles, harsher vacuum bakeouts, and higher reliability targets. Manufacturers pushing for longer MTBFs need materials that don’t add variability.

At DLX we invested in vacuum melting, precision cold rolling, and automated flatness metrology so our plates meet those new demands. We also added traceability so device manufacturers can tie field returns back to specific material lots for root cause analysis.

real-world impact — what our customers (anonymized) report

From working directly on production lines, customers switching to DLX 4J42 saw fewer brazing rework issues and a drop in early-life hermetic failures after qualification. In one case, optimizing plate flatness and switching to our recommended pre-braze treatment cut seal failures in half during a 500-cycle thermal test. Those are the kinds of practical improvements that show up in yield sheets and product reliability.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 | |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - | |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

third-party verification & quality assurance

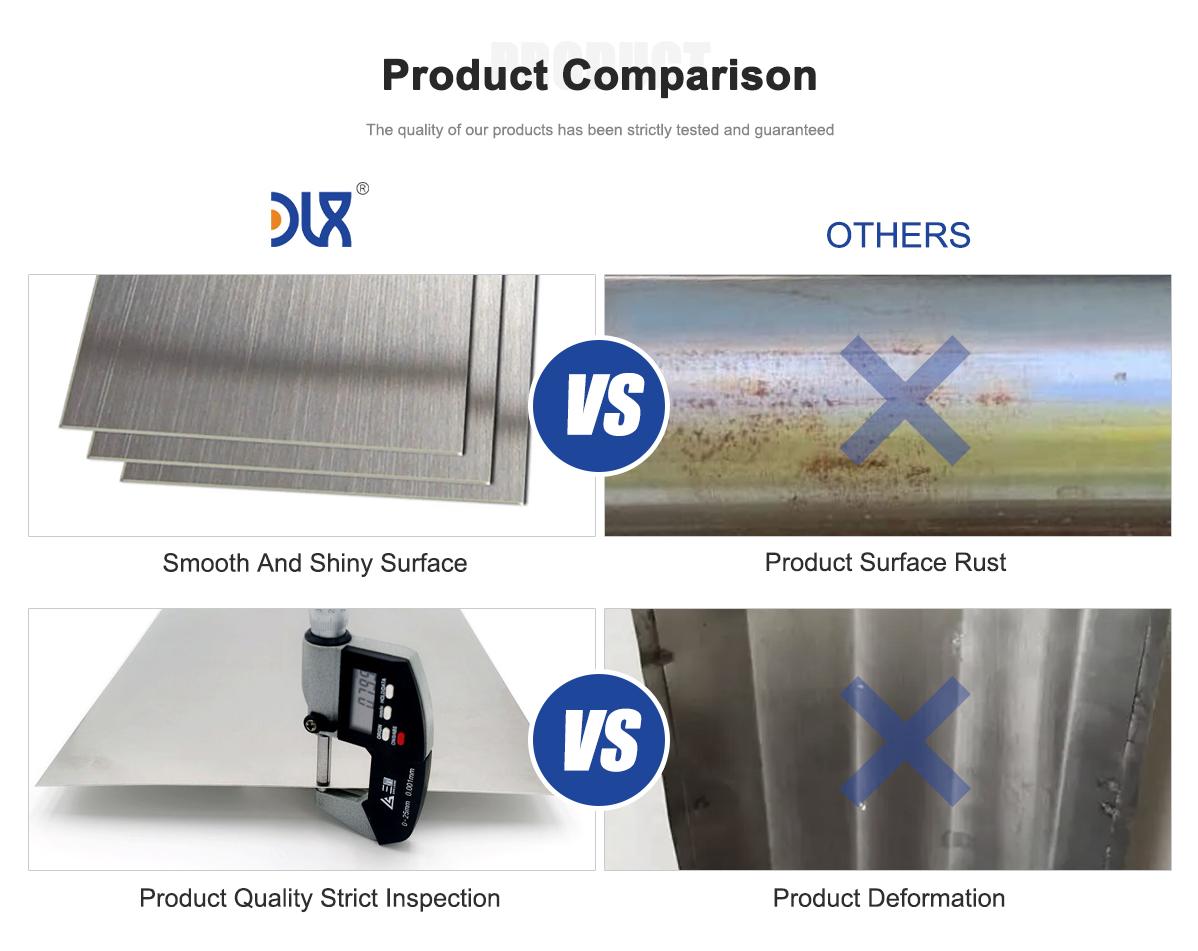

To back our claims, DLX routinely commissions independent lab reports for composition, mechanical properties, and expansion behavior. We maintain ISO 9001 systems, provide material test reports per shipment, and can include independent lab summaries on request to support audits and customer validations.

final notes — how DLX works with your team

We treat material supply as co-engineering. Send us small samples, CAD drawings, or failure data and we'll recommend the plate thickness, finish, and brazing profile. For complex devices we can run prototype lots with post-process testing and provide the data package you need for qualification.

Product snapshot — what we produce at DLX: precision-controlled 4J42 nickel-iron plates engineered for semiconductor packaging, hermetic feedthroughs, TO headers, and other electronic devices that demand an exact match between metal and glass or ceramic thermal expansion. We make these plates with vacuum melting, multi-stage rolling, and tight post-anneal quality control so your yields improve and your failure modes drop.

Material & typical composition

Nickel ~41–43%

Iron balance

Cobalt ~0.5–1.0% (for improved stability)

Trace elements tightly controlled (O, C, S, N kept very low)

Key mechanical/thermal properties (typical)

Density: ~8.2 g/cm³

CTE (20–300°C): ~4.7–5.2 × 10⁻⁶ /°C (matched to borosilicate & many glass types)

Tensile strength: ~500–650 MPa (depending on thickness & heat treatment)

Electrical resistivity (20°C): ~0.45–0.55 μΩ·m

why DLX 4J42 fits semiconductor & electronics work (short answer)

If you’re sealing glass or ceramic components to metal in small packages, the mismatch in thermal expansion is often the root cause of cracked seals and electrical failures. Our 4J42 plates are made to hold CTE within narrow bounds and to stay flat and clean through our processing—so brazes wet correctly and yields improve across thermal cycling.

technical comparison table — controlled expansion focus

| Parameter | DLX Controlled 4J42 Plate | Typical Controlled-Expansion Plate |

|---|---|---|

| Ni content control | 41–43% (±0.12%) | 41–43% (±0.4%) |

| CTE (20–300°C) | 4.9 ×10⁻⁶/°C (tight tolerance) | 4.9–5.3 ×10⁻⁶/°C |

| Flatness (per 200 mm) | ≤0.02 mm | ≤0.05 mm |

| Surface cleanliness | Sub-ppm particulate, cleaned & packaged | Typical industrial clean |

| Purity (O, C, S) | ≤0.002% combined | ≤0.01% combined |

| Batch traceability | Full lot reports + third-party test results | Limited or internal only |

| Certs & testing | ISO 9001, SGS/TÜV test reports available | Varies |

| Customization | Thickness 0.05–5.0 mm, cut-to-size, finishes | Limited sizes |

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

what glass types does 4J42 match best with?

4J42 is optimized for borosilicate and certain glass-ceramics used in semiconductor packaging. We always recommend running a short CTE match test with your exact glass lot — small glass composition shifts can matter at package scale.can i braze or vacuum-seal directly to DLX 4J42?

Yes. We supply plates pre-treated for optimal wetting with common silver braze alloys and provide recommended heating profiles. Our process reduces oxide films that cause poor wetting.what tolerance should i expect for CTE in production?

From our production lines we hold CTE variation tight enough that thermal mismatch failures in assembly decrease measurably. Typical CTE spread is within ±0.05 ×10⁻⁶/°C across a single lot.do you support small volume / prototype runs?

Absolutely. We work closely with R&D teams — sample strips, small batches, and prototype cutting are standard. We’ll also run the sample through a thermal cycle upon request and share the data.what surface finishes are available and why do they matter?

We offer bright annealed, oxidized, and nickel-plated finishes. For brazing, bright annealed with a controlled oxide gives best wetting; for feedthroughs that need plating, we can supply nickel-plated or other thin coatings per spec.how does DLX ensure lot-to-lot consistency?

Every melt and rolling pass is logged. We run chemical analysis, microstructure checks, and CTE testing on samples. For clients who need it, we include third-party verification (SGS/TÜV style reports) with shipments.will your plate work in high vacuum and high-temperature cycling?

Yes — our metallurgy and heat treatments are designed for vacuum compatibility. We control volatile impurities and surface contamination so outgassing is minimized in vacuum environments.can DLX advise on design and process optimization?

We consult. From choosing thickness to recommending brazing cycles and fixture design, our engineers (who’ve worked on volume semiconductor assemblies) help translate material specs into improved yields.