At DLX Alloy, we specialize in producing 4J42 Nickel-Iron Alloy Plate, an essential material in precision sealing between metal and glass components. 4J42, also known as Kovar equivalent, is a controlled expansion alloy composed primarily of iron (Fe), nickel (Ni ≈ 42%), and a small percentage of cobalt (Co). Its standout feature is its thermal expansion coefficient, which closely matches that of hard glass and ceramics, ensuring perfect sealing performance and structural integrity during extreme temperature changes.

Our alloy plates are produced with vacuum melting, hot rolling, and precision cold rolling technologies to achieve uniform grain structure, high dimensional accuracy, and excellent machinability. The plates exhibit stable mechanical properties, outstanding oxidation resistance, and reliable performance during long-term service in electronics, vacuum systems, and hermetic packaging.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

1J22 | 0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

| Property | Typical Value | Notes |

|---|---|---|

| Nickel (Ni) | 41–43% | Maintains expansion coefficient compatibility with glass |

| Cobalt (Co) | 0.5–1.0% | Enhances strength and thermal stability |

| Iron (Fe) | Balance | Provides structural integrity |

| Density | 8.2 g/cm³ | High density, stable under heat |

| Thermal Expansion Coefficient (20–300°C) | 4.7–5.2 × 10⁻⁶/°C | Matches glass, ideal for sealing |

| Electrical Resistivity (20°C) | 0.49 μΩ·m | Consistent electrical performance |

| Melting Point | 1450°C | High temperature endurance |

| Curie Point | ~360°C | Stable magnetic characteristics |

| Tensile Strength | 500–650 MPa | Excellent mechanical strength |

Applications

4J42 alloy plates play a crucial role in industries requiring airtight and durable seals between glass and metal parts.

Electronic Components – Used in vacuum tubes, transistor housings, and integrated circuit packages.

Optoelectronics – Suitable for laser diode housings and sensor assemblies.

Aerospace & Defense – Applied in hermetic connectors, feedthroughs, and pressure-resistant enclosures.

Medical Devices – Ideal for implantable and diagnostic electronic seals due to corrosion resistance.

High-Vacuum Equipment – Used in feedthrough plates and vacuum measurement instruments.

At DLX, we support custom plate thicknesses, special dimensions, and surface finishing treatments (oxidized, bright annealed, or nickel-coated) to meet customers’ diverse manufacturing needs.

Industry Trend Analysis

With the rapid growth of semiconductors, aerospace electronics, and vacuum packaging technologies, the demand for precision sealing materials like 4J42 has increased sharply. As devices get smaller and more reliable, glass-to-metal sealing alloys must offer ultra-low expansion, high purity, and stable thermal performance.

In recent years, we’ve observed a shift toward automated sealing systems that demand higher flatness and consistency in alloy plates. DLX Alloy’s advanced rolling and annealing lines achieve ±0.005 mm precision, ensuring consistent performance during thermal cycling.

Moreover, sustainability and recycling are becoming central to alloy production. DLX implements vacuum refining and material traceability systems, reducing waste and ensuring compliance with RoHS and REACH standards — a major advantage for clients requiring export certifications or third-party quality endorsements.

Why Choose DLX Alloy

Technical Expertise – Decades of experience in controlled expansion alloys, supporting industries from microelectronics to aerospace.

Precision Manufacturing – Our alloy plates undergo strict vacuum melting and multi-stage rolling for homogeneity and low residual stress.

Third-Party Validation – Materials tested by SGS and TÜV for composition, mechanical strength, and CTE stability.

Customization Capability – Thicknesses from 0.05 mm to 5 mm, with tailored surface treatments and edge cutting.

Global Supply Network – DLX serves clients in Europe, North America, and Asia, ensuring stable delivery and traceable documentation.

Technical Support – We assist with design selection, joining techniques, and temperature matching analysis for glass-to-metal assemblies.

Our long-term partners often highlight the stability of DLX 4J42 plates during vacuum sealing cycles, where performance consistency can make the difference between device reliability and production failure.

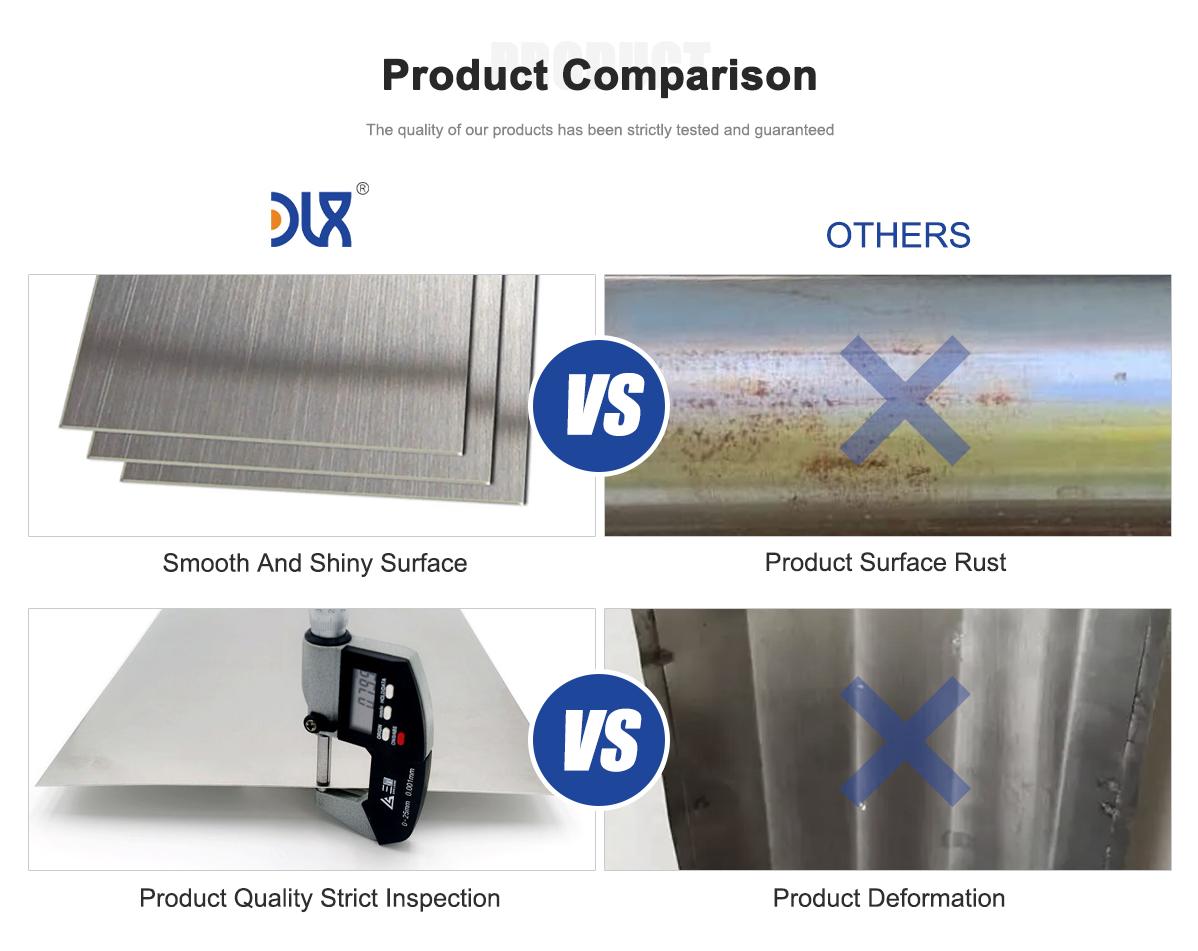

Comparison Table – DLX 4J42 vs. General Controlled Expansion Alloy

| Parameter | DLX 4J42 Alloy Plate | General Alloy Plate |

|---|---|---|

| Ni Content Control | ±0.15% | ±0.5% |

| Flatness | ≤0.02 mm | ≤0.05 mm |

| CTE (20–300°C) | 4.9 × 10⁻⁶/°C | 5.3 × 10⁻⁶/°C |

| Purity (O, C, S, N content) | ≤0.002% | ≤0.01% |

| Oxidation Resistance | Excellent | Average |

| Machinability | High precision | Moderate |

| Testing Certificate | SGS / TÜV / ISO | Limited |

| Export Qualification | Full documentation | Partial or none |

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What makes 4J42 suitable for glass-to-metal sealing?

Its coefficient of thermal expansion closely matches that of borosilicate glass, preventing cracks and ensuring a tight seal during temperature variations.

2. What’s the difference between 4J42 and Kovar?

They are chemically similar, but DLX 4J42 features tighter composition control and improved mechanical strength due to refined production and vacuum melting.

3. Can 4J42 plates be welded or brazed easily?

Yes, the material supports both TIG welding and silver-based brazing methods with good wetting behavior.

4. What size range do you provide?

DLX offers thicknesses from 0.05 mm to 5 mm, with width up to 400 mm and customizable lengths.

5. How do you guarantee consistency between batches?

Each batch undergoes chemical analysis, microstructure inspection, and expansion coefficient testing before shipment.

6. What surface finishes are available?

We supply plates with bright annealed, oxidized, or nickel-plated surfaces, depending on customer requirements.

7. Is DLX 4J42 certified for export?

Yes, DLX 4J42 meets ISO 9001, SGS, and RoHS certifications, suitable for international aerospace and electronics applications.

8. Can DLX support prototype or small-volume orders?

Absolutely. We provide sample cutting and small-batch production for R&D and pre-production testing needs.

Expert Insight

From our experience supplying vacuum electronic and semiconductor clients, the key performance factor isn’t only the alloy’s chemistry — it’s flatness, consistency, and clean surface finish. Our engineers work directly with customer sealing lines to optimize heating cycles, reducing thermal mismatch failures by up to 30%.

DLX 4J42 Alloy Plates have become a trusted choice for glass sealing applications in photodiodes, TO headers, and power module housings, where precision is everything. With stable production capacity and years of application expertise, DLX stands as a reliable partner for both R&D and mass production requirements.