The 4J06 soft magnetic alloy plate has become one of the key materials used in precision electromagnetic components such as relays, solenoids, and sensors. At DLX Alloy, we produce high-purity, high-stability 4J06 plates that deliver excellent performance in applications requiring precise control of magnetic fields. Our advanced processing technology ensures consistent mechanical strength, low magnetic loss, and stable permeability—meeting the demanding requirements of modern automation and energy systems.

4J06 is a nickel-iron alloy containing approximately 6% nickel, designed as a soft magnetic material with moderate saturation magnetic induction, low coercive force, and good mechanical workability. It’s particularly useful in electromagnetic actuators, magnetic switches, and relays, where both magnetic sensitivity and durability are critical.

DLX Alloy’s 4J06 plates are made using vacuum melting, precision rolling, and high-temperature hydrogen annealing to achieve an optimized grain structure and consistent magnetic response. Compared to higher nickel content alloys, 4J06 offers a better balance of magnetic performance and mechanical toughness, making it a versatile material for dynamic magnetic systems.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

1J22 | 0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

High saturation flux density (up to 1.6 T) – allows rapid magnetization in compact devices.

Low coercivity – improves energy efficiency and reduces hysteresis losses.

Excellent machinability – easy to stamp, cut, and form into complex shapes.

Good magnetic uniformity after annealing – ensures predictable, repeatable performance.

Stable properties under thermal cycling – suitable for long-term use in industrial environments.

Cost-effective compared to high-nickel alloys – ideal for large-scale production.

Applications

The 4J06 alloy plate is widely used in magnetic components that demand both strong magnetic induction and durability. Typical applications include:

Relays and Contactors – improves sensitivity and response time, ensuring fast switching and stable operation.

Solenoids – provides strong magnetic pull with minimal power consumption.

Magnetic Switches – enhances precision and reduces signal delay.

Electromagnetic Actuators – used in automation systems requiring repetitive movement and stable control.

Sensors and Transducers – ensures accuracy and repeatability in measuring devices.

Automotive Systems – utilized in fuel injectors, braking systems, and control valves.

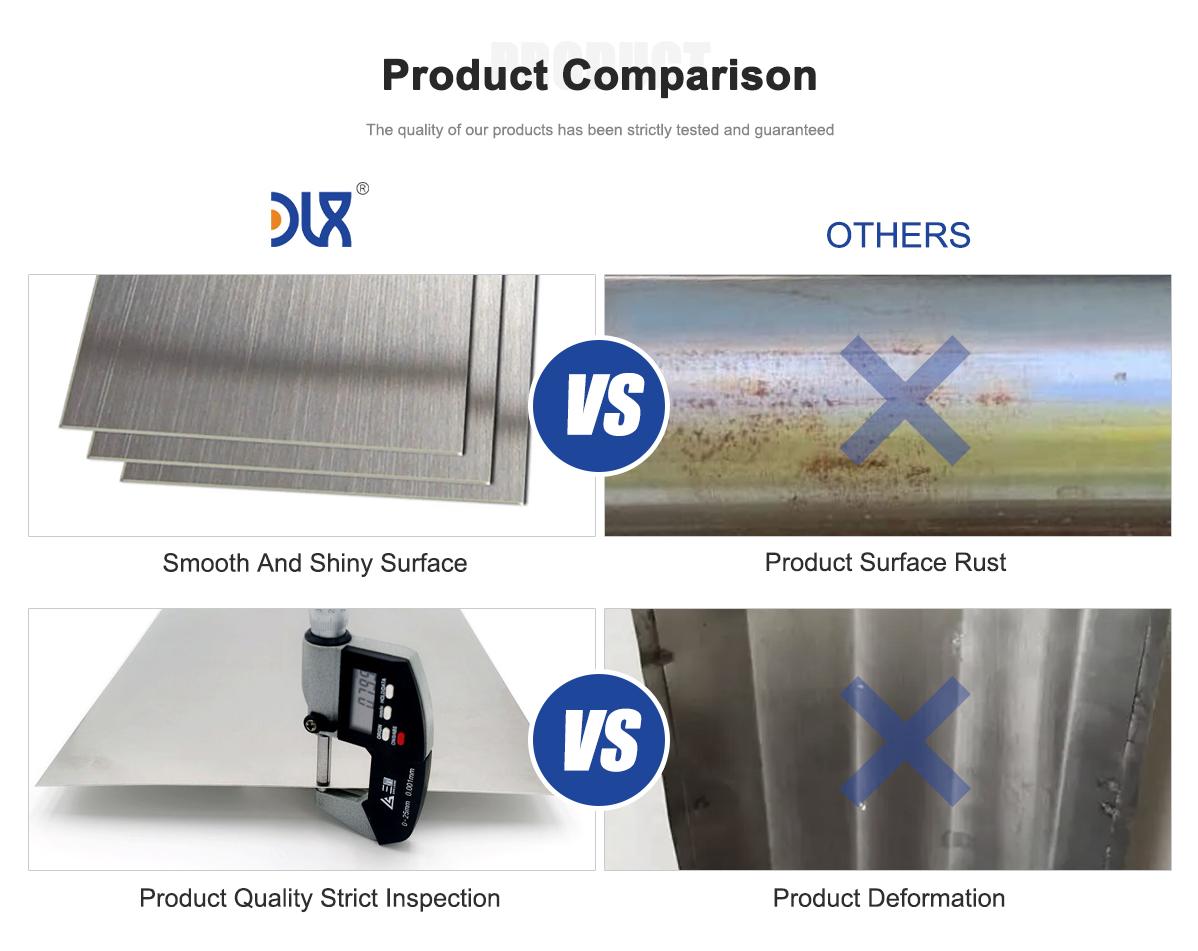

At DLX Alloy, we focus on tight dimensional tolerance and high surface finish, ensuring that every plate maintains uniform performance across the entire component batch.

| Property | 4J06 (DLX Alloy) | 4J29 (Kovar type) | 4J36 (Invar type) | 4J44 |

|---|---|---|---|---|

| Nickel Content (%) | 6 ± 1 | 29 ± 1 | 36 ± 1 | 44 ± 1 |

| Density (g/cm³) | 7.8 | 8.2 | 8.1 | 8.2 |

| Saturation Flux Density (T) | 1.5 – 1.6 | 1.0 | 0.6 | 0.8 – 1.0 |

| Maximum Permeability (μmax) | ≥ 4,000 | ≥ 10,000 | ≤ 10,000 | ≥ 40,000 |

| Coercive Force (A/m) | ≤ 30 | ≤ 10 | ≤ 10 | ≤ 8 |

| Curie Temperature (°C) | ~750 | ~450 | ~230 | ~480 |

| Machinability | Excellent | Moderate | Moderate | Good |

| Corrosion Resistance | Good | Excellent | Good | Excellent |

| Main Applications | Relays, Solenoids, Sensors | Sealing, Electronics | Expansion Control | Magnetic Shields, Transformers |

From this comparison, 4J06 stands out for its high magnetic induction, low cost, and excellent workability, making it the preferred option for electromagnetic components that require frequent magnetization and demagnetization cycles.

Industry Analysis

With the rise of industrial automation, electric vehicles, and intelligent control systems, the demand for soft magnetic materials like 4J06 has been expanding rapidly. These industries require alloys that combine magnetic efficiency, structural strength, and processing flexibility.

In particular, the relay and solenoid market has seen significant growth driven by the transition to smart energy systems and electromechanical automation. 4J06’s high magnetic response and durability make it a reliable choice for such systems, where precision, speed, and reliability are essential.

DLX Alloy is deeply involved in serving these markets, providing stable supply, customized specifications, and technical consultation for global clients. By optimizing material design and processing parameters, we help manufacturers achieve higher production efficiency and product reliability.

DLX Alloy Advantage

DLX Alloy has built a strong reputation for producing high-quality magnetic alloys that perform consistently in demanding applications. Here’s why clients choose our 4J06 plates:

Advanced Production Equipment – We use vacuum melting and cold rolling technology to ensure uniform alloy composition and surface quality.

Hydrogen Annealing Treatment – Enhances magnetic softness and eliminates internal stress, ensuring stable permeability.

Customizable Specifications – Available in various thicknesses from 0.1 mm to 10 mm, tailored to specific design needs.

Strict Quality Inspection – Each batch is tested for magnetic properties, dimensional precision, and mechanical performance.

Technical Expertise – Our engineers offer guidance on alloy selection, magnetic optimization, and heat treatment recommendations.

Global Delivery Support – DLX serves customers across Asia, Europe, and North America with reliable logistics and after-sales service.

Cost Efficiency – Optimized production processes help reduce material waste and improve cost-performance ratio.

Through these advantages, DLX Alloy ensures that our 4J06 soft magnetic plates deliver both technical reliability and economic value to customers worldwide.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is 4J06 alloy made of?

It’s a nickel-iron alloy with around 6% nickel, known for its high saturation magnetic induction and good workability.

2. What makes 4J06 suitable for relays and solenoids?

Its high magnetic flux density and low coercivity allow quick magnetic response, improving efficiency and durability in these components.

3. How does DLX Alloy ensure magnetic consistency?

We use vacuum melting and hydrogen annealing to create a uniform crystal structure and stable permeability across all batches.

4. What is the typical operating temperature for 4J06?

It can work reliably below 400°C, while its Curie point is around 750°C, offering excellent thermal stability.

5. Can DLX provide customized dimensions and surface finishes?

Yes, we offer custom-cut plates and precision polishing according to customer requirements.

6. How does 4J06 compare to high-nickel magnetic alloys?

4J06 offers higher saturation induction and better strength, while high-nickel alloys provide greater permeability—4J06 is ideal for actuating applications.

7. Is 4J06 easy to machine and form?

Yes, its composition allows excellent cold and hot processing, including stamping and drawing.

8. Why choose DLX Alloy’s 4J06 material?

Because DLX delivers superior consistency, flexible customization, and global technical support—all backed by years of manufacturing expertise.

Conclusion

DLX Alloy’s 4J06 Soft Magnetic Alloy Plate offers a perfect balance between magnetic performance, mechanical durability, and processability, making it a top choice for relays, solenoids, and electromagnetic actuators. As industries shift toward smarter and more efficient systems, materials like 4J06 become vital for ensuring reliable, fast-response performance.

With state-of-the-art production lines, stringent quality standards, and engineering innovation, DLX Alloy remains a trusted global partner for clients seeking dependable magnetic materials that perform under pressure and deliver long-term value.