At DLX Alloy, we specialize in precision-engineered soft magnetic alloys, and our 4J44 plate stands out as a reliable material choice for relays, transformers, magnetic amplifiers, and precision control systems. This alloy, known for its high magnetic permeability, excellent saturation flux density, and stable performance under varying conditions, plays a key role in improving efficiency and precision in modern electrical and electronic devices.

4J44, also known as Permalloy 44, is a nickel-iron soft magnetic alloy containing approximately 44% nickel. It’s characterized by high magnetic permeability and low coercive force, making it ideal for applications where precise magnetic control and rapid magnetization are critical.

At DLX Alloy, our 4J44 plates are manufactured through advanced vacuum melting, precision rolling, and annealing processes to ensure uniform composition, minimal internal stress, and optimized magnetic properties. These production standards allow the material to perform consistently even under complex magnetic field cycles and thermal variations.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

1J22 | 0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - | |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

High initial and maximum permeability – enabling strong magnetic response even under weak magnetic fields.

Low coercivity – allowing for efficient magnetization and demagnetization with minimal energy loss.

Good mechanical strength – maintains shape and structural integrity during processing and operation.

Excellent corrosion resistance – suitable for long-term use in demanding industrial environments.

Stable magnetic properties after heat treatment – reliable for precision components.

4J44 plates are widely used in magnetic and electronic devices that require precise control of magnetic fields. Common applications include:

Relays and Contactors – Ensures high sensitivity and rapid response by reducing hysteresis losses.

Transformers – Improves energy efficiency and minimizes heat generation in signal and pulse transformers.

Magnetic Shields – Provides effective shielding from electromagnetic interference in sensitive circuits.

Magnetic Amplifiers and Sensors – Enables stable signal processing in control systems.

Precision Instruments – Used in audio, aerospace, and navigation systems where magnetic accuracy is essential.

DLX Alloy’s processing technology guarantees consistent magnetic uniformity, making our 4J44 plate highly suitable for both mass production and customized industrial designs.

| Property | 4J44 (DLX Alloy) | 4J50 | 4J36 (Invar 36) | 4J79 |

|---|---|---|---|---|

| Nickel Content (%) | 44 ± 1 | 50 ± 1 | 36 ± 1 | 79 ± 1 |

| Density (g/cm³) | 8.2 | 8.25 | 8.1 | 8.7 |

| Saturation Flux Density (T) | 0.8 – 1.0 | 0.75 | 0.6 | 0.8 |

| Maximum Permeability (μmax) | ≥ 40,000 | ≥ 70,000 | ≤ 10,000 | ≥ 100,000 |

| Coercive Force (A/m) | ≤ 8 | ≤ 5 | ≤ 10 | ≤ 4 |

| Curie Temperature (°C) | ~480 | ~400 | ~230 | ~450 |

| Machinability | Good | Fair | Moderate | Fair |

| Corrosion Resistance | Excellent | Good | Good | Excellent |

| Typical Applications | Relays, Transformers, Magnetic Shields | Precision Cores | Thermal Expansion Control | Sensors, Transformers |

From the table, it’s clear that 4J44 offers a balanced combination of magnetic permeability, mechanical strength, and stability, making it the preferred choice for medium-field applications.

In recent years, the demand for soft magnetic materials like 4J44 has grown significantly due to rapid advancements in automation, energy systems, and digital control technologies. The global market is driven by industries focusing on miniaturization, energy efficiency, and signal accuracy—all of which rely on materials with low energy loss and stable magnetic performance.

Relays and transformers used in renewable energy systems, smart grids, and electric vehicles require materials that can maintain consistent magnetic properties under dynamic conditions. The 4J44 alloy fits perfectly into these trends, offering both performance reliability and manufacturing flexibility.

At DLX Alloy, we continue to optimize the processing precision and magnetic heat treatment of our 4J44 products to meet the latest industrial standards (ASTM, GB, ISO) and global customer requirements.

DLX Alloy Advantage

DLX Alloy stands out in the competitive market through the following strengths:

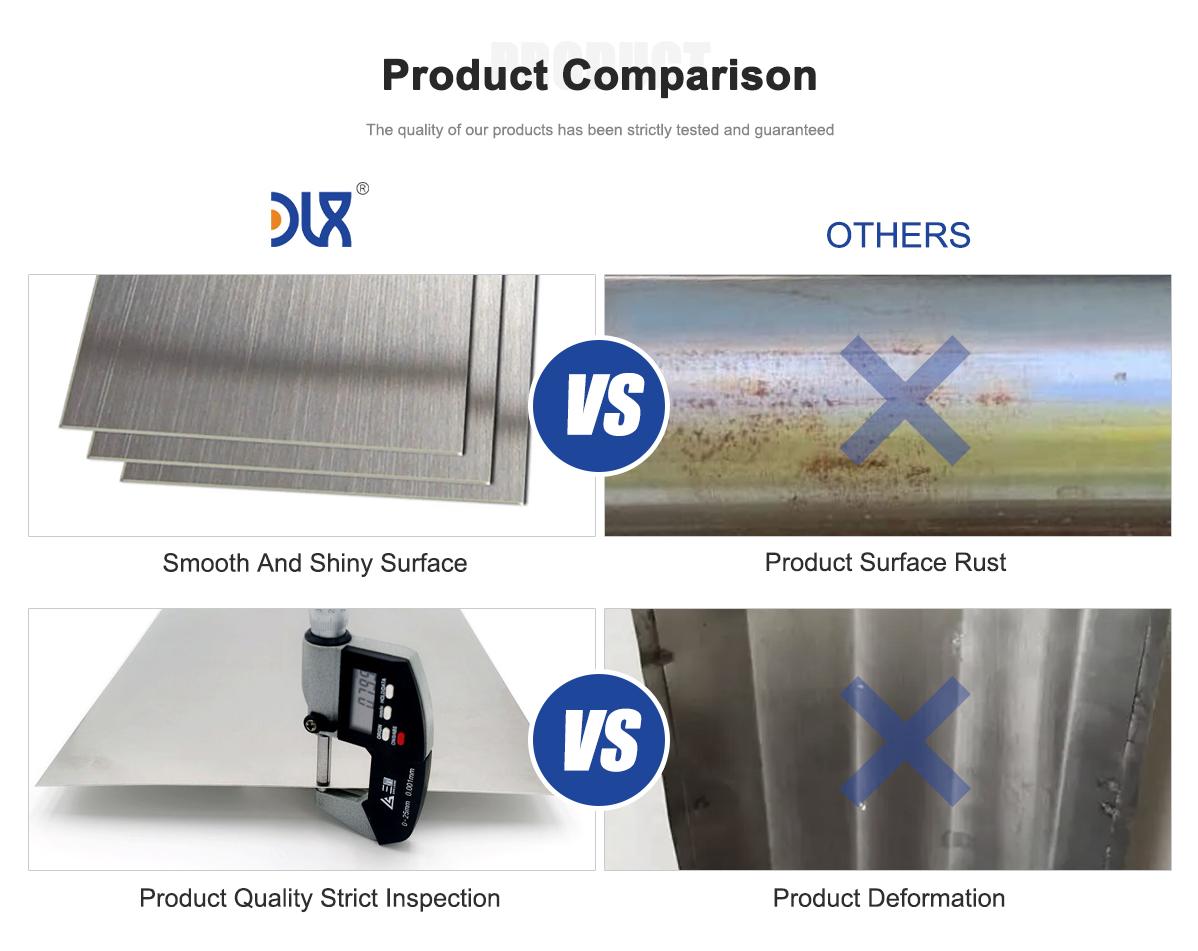

Precision Manufacturing – Every plate undergoes vacuum melting and fine cold rolling, ensuring uniform magnetic structure.

Advanced Heat Treatment – Controlled annealing under a hydrogen-protected atmosphere guarantees high permeability and low coercivity.

Custom Thickness Options – Available from 0.1 mm to 10 mm, tailored to customer specifications.

Strict Quality Control – Each batch is tested for magnetic, mechanical, and dimensional accuracy using advanced instruments.

Global Delivery and Technical Support – DLX provides professional consultation for material selection, design optimization, and export compliance.

Sustainable Production – We implement environmentally responsible manufacturing practices that minimize waste and energy usage.

This comprehensive approach ensures our clients receive consistent, high-performance 4J44 materials suitable for high-end industrial and electronic systems.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is 4J44 alloy made of?

It’s a nickel-iron alloy with approximately 44% nickel, offering excellent magnetic properties and stable performance.

2. How does 4J44 differ from 4J50 or 4J79?

4J44 has moderate permeability and higher mechanical strength, making it ideal for relays and transformers that need balanced performance.

3. Can DLX supply custom sizes and thicknesses?

Yes. We provide custom plate thicknesses and dimensions to match specific application requirements.

4. What is the maximum working temperature for 4J44?

The Curie temperature is around 480°C, but it is typically used below 400°C to ensure stable magnetic behavior.

5. How is 4J44 plate heat-treated?

It’s annealed in a hydrogen-protected furnace to achieve high permeability and low coercive force.

6. What industries commonly use 4J44?

It’s used in electronics, aerospace, energy systems, instrumentation, and automation equipment.

7. Is 4J44 corrosion-resistant?

Yes, especially after annealing and surface treatment, making it suitable for long-term service in industrial environments.

8. Why choose DLX Alloy’s 4J44 plates?

DLX offers precision control, consistent magnetic performance, and tailored production capabilities—ensuring our clients receive materials optimized for their specific systems.

Conclusion

DLX Alloy’s High Permeability 4J44 Plate delivers the ideal combination of magnetic efficiency, durability, and process reliability for relays, transformers, and precision instruments. As industries move toward smarter, more energy-efficient systems, materials like 4J44 are essential in ensuring stable, low-loss performance across a wide range of applications.

With our advanced manufacturing technology, strict quality control, and engineering expertise, DLX Alloy remains a trusted global supplier of high-grade 4J44 materials—driving performance, reliability, and innovation in every application.