The 1J50 Nickel-Iron magnetic alloy plate, also known internationally as Permalloy 80 or Ni80Fe20, is one of the most widely used soft magnetic materials in precision electronic systems. It combines high permeability, low coercivity, and stable magnetic performance, making it an ideal choice for magnetic shielding, transformers, inductors, and precision sensors.

At DLX Alloy, we specialize in developing and producing high-purity 1J50 plates with consistent composition and tight dimensional control. Our advanced melting and rolling processes ensure that each sheet provides exceptional soft magnetic properties and reliable performance in demanding industrial environments.

1J50 is a nickel-iron alloy containing approximately 80% nickel and 20% iron. This composition gives it remarkable magnetic softness, allowing magnetic domains to switch easily and with minimal energy loss. It also exhibits excellent resistance to magnetostriction and maintains stable performance under a range of magnetic field intensities.

Its physical characteristics make it suitable for low-frequency AC magnetic circuits and applications that demand precision magnetic response, such as in measuring devices, high-sensitivity transformers, and electromagnetic relays.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

1J22 | 0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - | |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

The 1J50 alloy plate is widely used across multiple sectors, including:

Transformer cores for high-sensitivity instruments

Electromagnetic shielding in medical and aerospace electronics

Magnetic amplifiers and sensors in industrial control systems

Magnetic field measurement equipment

Relay and choke cores requiring stable permeability

At DLX Alloy, we supply 1J50 plates tailored to each customer’s application needs, offering customized dimensions, annealed conditions, and surface finishes.

Material Comparison Table

| Property / Alloy | 1J50 (Ni80Fe20) | 1J79 (Ni79Fe21) | 1J85 (Supermalloy) | Silicon Steel |

|---|---|---|---|---|

| Nickel Content (%) | 80 | 79 | 80 | — |

| Permeability (μmax) | 100,000–150,000 | 80,000–120,000 | 500,000+ | <10,000 |

| Coercivity (A/m) | ≤ 40 | ≤ 60 | ≤ 10 | ≥ 100 |

| Resistivity (μΩ·cm) | 50–60 | 50 | 80–90 | 45 |

| Saturation Induction (T) | 0.75 | 0.8 | 0.7 | 1.5–2.0 |

| Heat Treatment | Hydrogen annealing | Vacuum annealing | Hydrogen annealing | — |

| Applications | Transformers, sensors | Relays, amplifiers | Precision coils | Power transformers |

This comparison shows why 1J50 stands out for applications requiring balance between permeability, cost, and stability. While materials like Supermalloy have higher permeability, 1J50 offers a much more cost-effective solution for most commercial and industrial applications.

The demand for nickel-iron magnetic alloys like 1J50 continues to grow as industries push toward miniaturization, higher efficiency, and electromagnetic stability. Emerging sectors such as smart grids, electric vehicles, and renewable energy systems increasingly rely on precision magnetic components.

With advancements in sensor technology and high-frequency electronic equipment, soft magnetic materials are shifting toward high-purity, low-loss alloys that can perform under variable conditions. DLX Alloy’s focus on refining microstructure and composition uniformity ensures our 1J50 plates meet the evolving technical requirements of modern energy and electronics systems.

Why Choose DLX Alloy

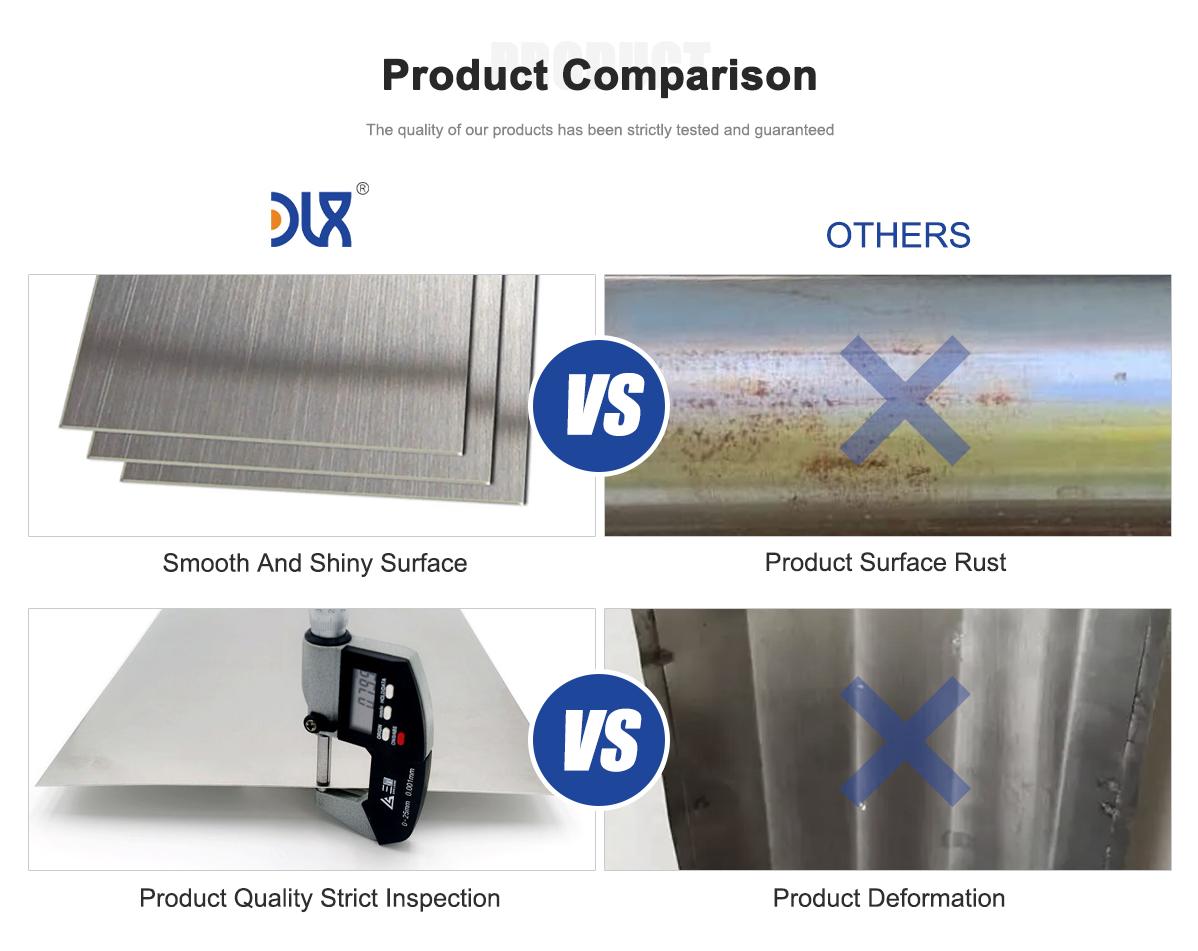

At DLX Alloy, we combine metallurgical expertise, advanced production facilities, and strict quality control to ensure consistent magnetic performance. Our production advantages include:

Vacuum melting furnaces for superior purity and homogeneity

Precision rolling and annealing to enhance permeability

Flexible customization in size, surface condition, and magnetic orientation

Comprehensive testing for coercivity, permeability, and resistivity

We serve clients in electronic manufacturing, medical devices, aerospace, and energy systems, offering reliable soft magnetic materials with competitive pricing and fast delivery.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the main composition of 1J50?

1J50 is a nickel-iron alloy containing around 80% nickel and 20% iron.

2. What are the key properties of 1J50?

It features high magnetic permeability, low coercivity, and excellent magnetic stability.

3. What applications use 1J50 plates?

Common uses include transformer cores, sensors, electromagnetic shielding, and precision instruments.

4. How does 1J50 compare to 1J85?

1J85 (Supermalloy) has higher permeability but is more expensive and harder to process. 1J50 offers a balanced performance-cost ratio.

5. Can 1J50 be used in high-frequency applications?

It performs best in low-frequency magnetic circuits. For high-frequency uses, specialized alloys may be better.

6. What heat treatment improves 1J50’s properties?

Hydrogen annealing significantly enhances its magnetic softness and uniformity.

7. What surface finishes are available from DLX Alloy?

We provide polished, cold-rolled, and annealed surfaces depending on customer requirements.

8. Does DLX Alloy offer custom thickness or size?

Yes, we offer tailored thicknesses from 0.1 mm to several millimeters, depending on application needs.

Conclusion

1J50 Nickel-Iron Magnetic Plate remains a cornerstone material in the field of precision electromagnetic manufacturing. Its balance of magnetic performance, stability, and affordability continues to make it an industry favorite. As technological requirements evolve, DLX Alloy remains dedicated to providing optimized, reliable, and application-driven solutions for customers worldwide.