1J50, a nickel-iron soft magnetic alloy, is widely recognized for its exceptional magnetic permeability, low coercivity, and stable performance in alternating magnetic fields. As one of the core materials for transformer and inductor production, it provides the magnetic efficiency and consistency required in precision electronic and power systems. At DLX Alloy, we focus on manufacturing high-quality 1J50 plates with superior uniformity and customized performance, meeting the needs of advanced magnetic circuit applications.

1J50 is primarily composed of about 50% nickel and 50% iron, making it a balanced magnetic alloy with both high permeability and moderate saturation induction. It falls under the soft magnetic alloy category, meaning it can be easily magnetized and demagnetized, offering low magnetic loss in AC circuits.

Key characteristics include:

-

High magnetic permeability: ensures efficient magnetic field conduction.

-

Low coercive force: reduces energy loss during magnetization cycles.

-

Stable performance over wide temperature ranges: up to 450°C.

-

Excellent consistency in alternating fields.

-

Good mechanical strength and processability.

At DLX Alloy, we use vacuum induction melting and precise annealing processes to ensure chemical purity and minimize inclusions. This gives our 1J50 plate exceptional stability and magnetic uniformity, which is crucial for energy systems, sensors, and relay applications.

Alloy Composition Table

|

Alloy Grades |

C |

S |

P |

Mn |

Si |

Ni |

Cr |

Co |

Mo |

Cu |

Al |

Nb |

Fe |

Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1J06 |

0.04 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

5.5-6.5 |

- |

Rest |

- |

|

1J12 |

0.03 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

11.6-12.4 |

- |

Rest |

- |

|

1J17 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

- |

15.5-16.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J18 |

0.03 |

0.02 |

0.02 |

0.3-0.7 |

≤0.15 |

0.5-0.7 |

17-18.5 |

- |

- |

- |

- |

- |

Rest |

Ti: 0.3-0.7 |

|

1J22 |

0.04 |

0.02 |

0.02 |

≤0.3 |

≤0.3 |

≤0.5 |

- |

49-51 |

- |

≤0.2 |

- |

- |

Rest |

V: 0.8-1.8 |

|

1J30 |

0.04 |

0.02 |

0.02 |

≤0.40 |

≤0.30 |

29.5-30.5 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J36 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

35.0-37.0 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J38 |

0.03 |

0.05 |

0.02 |

0.3-0.6 |

0.15-0.3 |

37.5-38.5 |

12.5-13.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J46 |

0.03 |

0.02 |

0.02 |

0.6-1.1 |

0.15-0.3 |

45.0-46.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J50 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J51 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J54 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

1.1-1.4 |

49.5-51 |

3.8-4.2 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J76 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.0-76.5 |

1.8-2.2 |

- |

- |

4.8-5.2 |

- |

- |

Rest |

- |

|

1J77 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.5-78 |

- |

- |

3.9-4.5 |

4.8-6.0 |

- |

- |

Rest |

- |

|

1J79 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

0.3-0.5 |

78.5-80.0 |

- |

- |

3.8-4.1 |

≤0.2 |

- |

- |

Rest |

- |

|

1J80 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

1.1-1.5 |

79.0-81.5 |

2.6-3.0 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J85 |

0.03 |

0.02 |

0.02 |

0.3-0.60 |

0.15-0.3 |

79.0-81.0 |

- |

- |

4.8-5.2 |

≤0.2 |

- |

- |

Rest |

- |

|

1J87 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

≤0.3 |

78.5-80.5 |

- |

- |

1.6-2.2 |

- |

- |

6.5-7.5 |

Rest |

- |

For more details, pls directly contact us.

Due to its outstanding magnetic softness and stability, 1J50 plates are widely used in electromagnetic devices that demand high sensitivity and low energy consumption.

Typical applications include:

-

Transformer cores: ensures efficient energy transfer and minimal hysteresis loss.

-

Magnetic amplifiers: improves signal control and magnetic response.

-

Relays and solenoids: enables precise magnetic switching.

-

Electromagnetic shielding components: reduces magnetic interference.

-

Sensors and inductors: used in precision control and detection circuits.

-

Magnetic memory and storage devices.

In industries like aerospace, telecommunications, medical electronics, and energy systems, 1J50’s balance between magnetic performance and durability makes it a preferred material for engineers seeking both efficiency and reliability.

As modern technology evolves, energy efficiency and miniaturization are major focuses in electrical design. The demand for materials that deliver high magnetic permeability with reduced losses is increasing rapidly.

Soft magnetic alloys like 1J50 play a critical role in:

-

Renewable energy systems, improving transformer efficiency.

-

Electric vehicles, where compact magnetic components are vital.

-

Smart grid technologies, which require stable and low-loss magnetic circuits.

-

Automation and robotics, enhancing precision sensor performance.

At DLX Alloy, we continue to refine our production of magnetic alloys to align with these trends. Through custom heat treatment and controlled rolling, we enhance 1J50’s microstructure, achieving a higher saturation flux density and better magnetic uniformity.

| Property | 1J50 Alloy Plate | 1J79 Alloy Plate | 4J50 Alloy Plate | 4J49 Alloy Plate |

|---|---|---|---|---|

| Nickel Content (%) | 48–50 | 78–80 | 49–51 | 49–50 |

| Magnetic Permeability (μ) | High | Very High | High | High |

| Coercive Force (A/m) | ≤ 50 | ≤ 40 | ≤ 50 | ≤ 45 |

| Resistivity (μΩ·cm) | 40–50 | 60–70 | 45–50 | 50–60 |

| Curie Temperature (°C) | ~500 | ~450 | ~500 | ~480 |

| Density (g/cm³) | 8.2 | 8.7 | 8.2 | 8.3 |

| Processability | Excellent | Good | Excellent | Excellent |

| Typical Use | Transformers, Relays | Magnetic Shields | Magnetic Circuits | Sensors |

From this comparison, 1J50 offers a practical balance of magnetic performance, thermal stability, and cost efficiency — ideal for mid- to high-level precision magnetic components.

Why Choose DLX Alloy

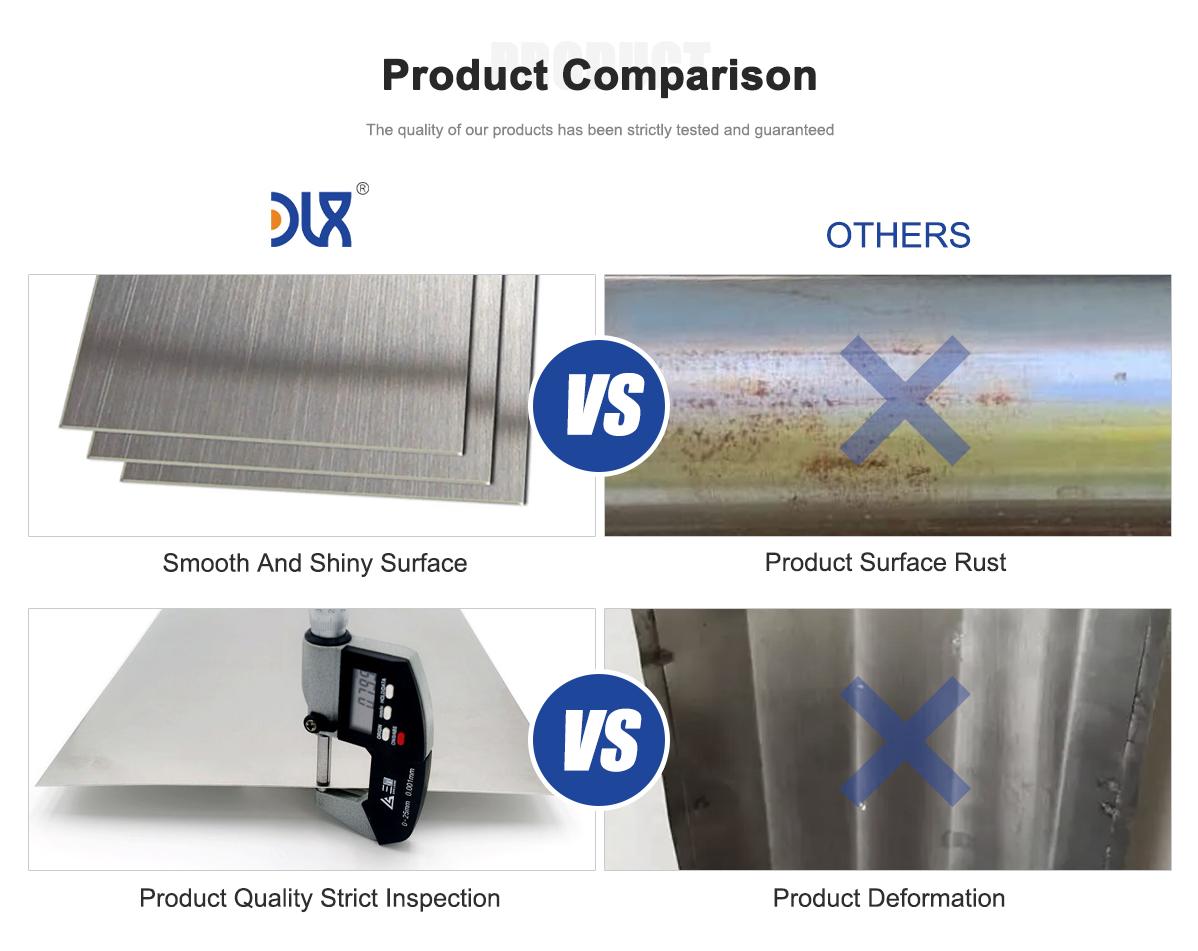

At DLX Alloy, we take pride in combining material science expertise with precision engineering. Every 1J50 plate we produce undergoes rigorous testing to ensure performance stability and consistent quality.

Our strengths include:

-

Vacuum melting and refining: eliminates impurities and ensures magnetic uniformity.

-

Precision rolling and heat treatment: optimizes grain structure for superior permeability.

-

Tight dimensional tolerances: ±0.01mm for precision assembly and integration.

-

Flexible customization: adjustable annealing and surface finishing for specific use cases.

-

Comprehensive quality control: includes permeability, coercivity, and composition analysis for every batch.

DLX Alloy’s production capabilities allow for consistent performance in both small-scale prototypes and mass industrial manufacturing. Our material engineers collaborate with customers to fine-tune parameters for specific transformer and electromagnetic designs.

DLX Alloy Production and Quality

We use advanced vacuum melting furnaces and high-precision cold rolling mills to manufacture 1J50 plates. This ensures chemical uniformity, mechanical strength, and excellent flatness.

Each production batch is tested for:

-

Magnetic permeability (μi and μmax)

-

Coercive force (Hc)

-

Saturation flux density (Bs)

-

Resistivity and density

-

Surface roughness and dimensional accuracy

All data is recorded and traceable, ensuring customers receive materials that meet their exact technical requirements. DLX’s laboratory also conducts aging and thermal cycle testing to simulate real-world performance and confirm long-term stability.

Sustainability and Future Outlook

Sustainability in modern industry requires energy-efficient materials and long-life magnetic systems. The 1J50 alloy’s low energy loss and long service life directly contribute to lower operational costs and carbon footprint.

DLX Alloy supports sustainable development by:

-

Reducing waste and emissions in production.

-

Recycling alloy scraps efficiently.

-

Optimizing melting and annealing processes for energy efficiency.

As industries like electric transportation, smart devices, and automation continue to expand, 1J50 will remain an indispensable magnetic material for next-generation power and electronic systems. DLX Alloy is fully equipped to meet this growing global demand with technical excellence and steady production capacity.

1J50 soft magnetic alloy plate stands as a cornerstone material for high-efficiency transformers, inductors, and magnetic circuits. With high permeability, low coercivity, and thermal stability, it offers an ideal balance between performance and reliability in precision applications.

DLX Alloy’s commitment to quality and innovation ensures that every 1J50 plate delivers consistent magnetic behavior, optimal surface finish, and precise dimensional control. Whether for large-scale energy systems or microelectronic devices, our 1J50 products provide the magnetic foundation for modern technological advancement.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the main composition of 1J50 alloy?

It contains about 50% nickel and 50% iron, providing excellent soft magnetic performance.

2. What are the main uses of 1J50 plates?

They are widely used in transformers, inductors, relays, and magnetic amplifiers.

3. What makes 1J50 a soft magnetic alloy?

It has low coercivity and can easily magnetize and demagnetize without significant energy loss.

4. What is the Curie temperature of 1J50?

Around 500°C, allowing stable operation under high temperatures.

5. Can DLX customize plate thickness?

Yes, DLX offers a wide range of plate thicknesses and sizes according to customer specifications.

6. Is 1J50 suitable for AC magnetic fields?

Yes, it performs very well under alternating magnetic fields due to low hysteresis loss.

7. How does DLX ensure magnetic uniformity?

Through vacuum melting, strict heat control, and advanced annealing processes.

8. Does DLX provide export packaging and testing reports?

Yes, each shipment is vacuum-packed with a full magnetic and chemical inspection report.