Our 1J75 soft magnetic alloy wire is a high-performance nickel-iron alloy built to deliver reliable, durable performance in aerospace sensors. With its high permeability and low core losses, it’s the top choice for industries like aerospace, electronics, and telecommunications. Let’s dive into what makes this wire a game-changer, explore its role in today’s cutting-edge markets, and highlight why our company is your best partner for this advanced material.

For more details, pls directly contact us.

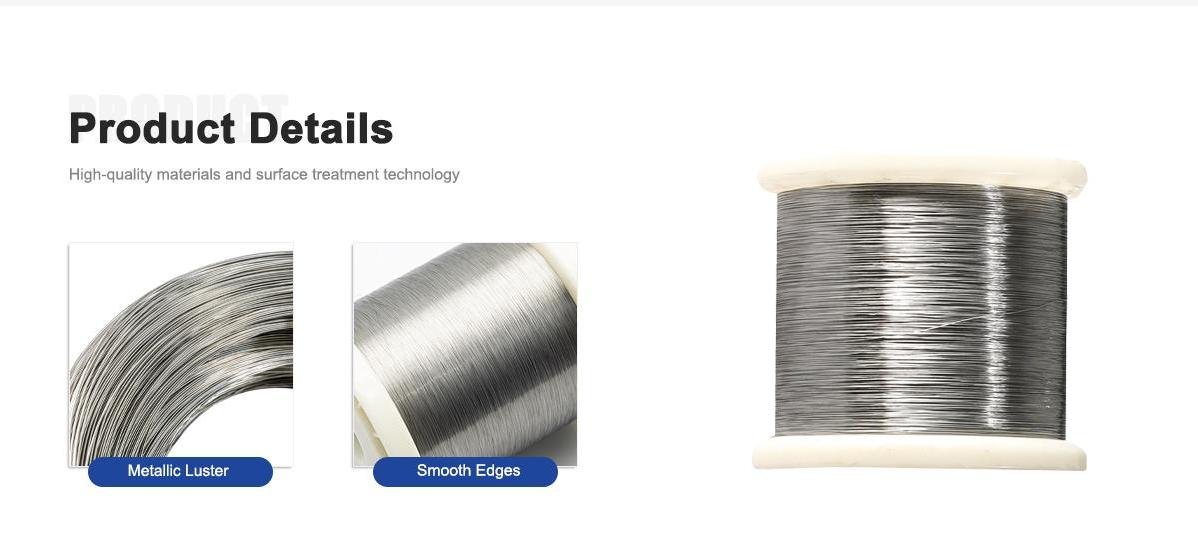

Our 1J75 soft magnetic alloy wire is a precision-crafted alloy with ~75% nickel and the balance iron, designed for exceptional magnetic properties. It boasts an initial permeability of up to 80,000, low coercivity (2–10 A/m), and very low core losses, making it perfect for aerospace sensors. Available in diameters from 0.1mm to 2.0mm and in soft or annealed conditions, this wire is fully customizable to fit your project’s specs. Whether you’re designing sensors for harsh aerospace environments or high-frequency chokes, our 1J75 wire ensures top durability and precision.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 | |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - | |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

The soft magnetic materials market is booming, driven by advancements in aerospace, 5G telecommunications, and renewable energy systems. Demand for durable, high-permeability alloys like 1J75 is surging as industries prioritize reliable components for sensors and high-frequency applications. Market trends show strong growth in the soft magnetic sector, with aerospace and electronics leading the charge for materials that excel in precision and stability under tough conditions. The push for compact designs and advanced manufacturing techniques, like precision winding, is creating new opportunities for 1J75 wire. Our alloy is perfectly positioned to meet these evolving demands.

Our 1J75 soft magnetic alloy wire excels in a range of high-precision applications:

Aerospace Sensors: Its high permeability and durable magnetic properties ensure precise, reliable performance in harsh environments.

High-Frequency Chokes: The wire’s low core losses make it ideal for efficient chokes in telecom and power systems.

Magnetic Shielding: Near-zero magnetostriction and high permeability provide superior protection for sensitive electronics.

Transformers: Its excellent magnetic properties support efficient, high-frequency transformers.

Renewable Energy: It boosts efficiency in inverters and chokes for solar and wind energy systems, supporting green tech.

This wire’s versatility makes it a critical component for industries chasing precision and durability.

Comparison Parameters Table

Parameter | 1J75 Soft Magnetic Wire | Lower-Nickel Alloys | Silicon Steel |

|---|---|---|---|

Initial Permeability | Up to 80,000 | 10,000–40,000 | 500–2,000 |

Magnetic Saturation (T) | 0.9 | 1.4–1.8 | 1.8–2.0 |

Coercive Force (A/m) | 2–10 | 10–20 | 50–100 |

Core Loss | Very Low | Low–Moderate | High |

Resistivity (μΩ·m) | 0.50 | 0.50–0.60 | 0.47–0.50 |

Magnetostriction (10⁻⁶) | Near Zero | 10–25 | 10–30 |

Applications | Sensors, shielding, chokes | Relays, inductors | Power transformers |

Sensor Durability | Superior | Moderate | Low |

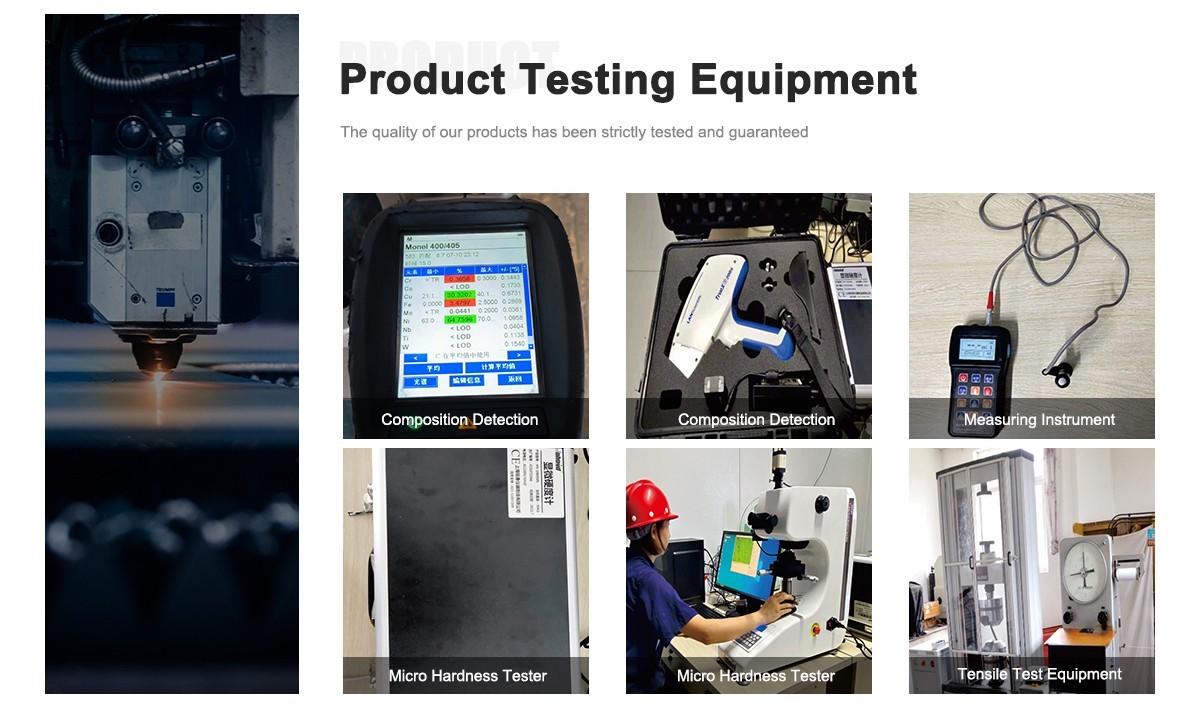

When it comes to 1J75 soft magnetic alloy wire, we’re ahead of the curve. With over 20 years of expertise in high-performance alloys, we control every stage of production—from alloy formulation to precision annealing—ensuring top-notch quality. We offer tailored solutions, customizing wire sizes and tempers to fit your sensor and choke designs. Our rigorous testing meets global standards like ASTM A753, and we provide free samples (with buyers covering shipping) to let you test our wire’s performance. With fast lead times—samples in 10–15 days—and a global supply chain, we keep your projects on track. Our deep expertise in aerospace applications gives you a competitive edge.

Why Choose Our 1J75 Soft Magnetic Alloy Wire?

Our 1J75 soft magnetic alloy wire is built for industries that demand durability, high permeability, and low core losses in aerospace sensors and beyond. From precision sensors to efficient chokes, it’s designed to power your most advanced projects. Backed by our expertise, customization options, and commitment to quality, we’re here to help you succeed. Ready to enhance your aerospace designs? Contact us today to explore how our 1J75 wire can drive your success.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is 1J75 soft magnetic alloy wire made of?

It’s a nickel-iron alloy with ~75% nickel, iron, and trace elements, designed for high permeability and durability.What makes 1J75 wire unique?

It offers high initial permeability (up to 80,000), low coercivity (2–10 A/m), and low core losses for reliable sensor performance.What are the main applications of 1J75 wire?

It’s used in aerospace sensors, transformers, magnetic shielding, and inductors in electronics and telecom.How does 1J75 wire perform in aerospace sensors?

Its high permeability and durable magnetic properties ensure precise, stable performance in harsh aerospace environments.Can 1J75 soft magnetic alloy wire be customized?

Yes, we offer custom diameters (0.1mm–2.0mm) and tempers (soft or annealed) to meet specific project needs.Which industries rely on 1J75 wire?

Aerospace, electronics, telecommunications, automotive, and renewable energy sectors use it for high-precision components.How does 1J75 wire compare to other alloys?

It outperforms lower-nickel alloys and silicon steel with higher permeability and better durability for sensor applications.Is 1J75 wire suitable for high-frequency applications?

Absolutely, its low core losses and high permeability make it ideal for high-frequency aerospace sensors and chokes.