At DLX Alloy, we specialize in 4J45 controlled Expansion Alloy plates, engineered for high-precision electronic and semiconductor components that demand unmatched dimensional stability and repeatable performance. Through years of experience supplying vacuum-sealed and hermetically packaged parts for the semiconductor, aerospace, and optoelectronic industries, we’ve learned that the key to product reliability isn’t just the chemistry of the material—it’s how consistently that chemistry performs under heat, vacuum, and time.

Our High Stability 4J45 Plate is designed to maintain tight thermal expansion control, flatness, and structural integrity during repeated thermal cycling. Each plate undergoes vacuum melting, multi-stage rolling, and fine-grain annealing to ensure low internal stress, high purity, and a clean surface suitable for brazing and plating operations.

4J45 is a nickel–iron alloy containing about 45% nickel, with the balance being high-purity iron and minor elements precisely adjusted to stabilize its thermal expansion. The result is a material with a coefficient of thermal expansion (CTE) that closely matches ceramics and hard glass used in electronic components.

DLX 4J45 plates are particularly suitable for metal-to-glass sealing, semiconductor device bases, sensor housings, and high-vacuum feedthroughs. Because of our advanced rolling and annealing processes, the plates feature uniform microstructure, low porosity, and controlled grain size, allowing consistent performance from prototype to mass production.

|

Alloy Grades |

C |

S |

P |

Mn |

Si |

Ni |

Cr |

Co |

Mo |

Cu |

Al |

Nb |

Fe |

Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1J06 |

0.04 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

5.5-6.5 |

- |

Rest |

- |

|

1J12 |

0.03 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

11.6-12.4 |

- |

Rest |

- |

|

1J17 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

- |

15.5-16.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J18 |

0.03 |

0.02 |

0.02 |

0.3-0.7 |

≤0.15 |

0.5-0.7 |

17-18.5 |

- |

- |

- |

- |

- |

Rest |

Ti: 0.3-0.7 |

|

1J22 |

0.04 |

0.02 |

0.02 |

≤0.3 |

≤0.3 |

≤0.5 |

- |

49-51 |

- |

≤0.2 |

- |

- |

Rest |

V: 0.8-1.8 |

|

1J30 |

0.04 |

0.02 |

0.02 |

≤0.40 |

≤0.30 |

29.5-30.5 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J36 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

35.0-37.0 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J38 |

0.03 |

0.05 |

0.02 |

0.3-0.6 |

0.15-0.3 |

37.5-38.5 |

12.5-13.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J46 |

0.03 |

0.02 |

0.02 |

0.6-1.1 |

0.15-0.3 |

45.0-46.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J50 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J51 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J54 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

1.1-1.4 |

49.5-51 |

3.8-4.2 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J76 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.0-76.5 |

1.8-2.2 |

- |

- |

4.8-5.2 |

- |

- |

Rest |

- |

|

1J77 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.5-78 |

- |

- |

3.9-4.5 |

4.8-6.0 |

- |

- |

Rest |

- |

|

1J79 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

0.3-0.5 |

78.5-80.0 |

- |

- |

3.8-4.1 |

≤0.2 |

- |

- |

Rest |

- |

|

1J80 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

1.1-1.5 |

79.0-81.5 |

2.6-3.0 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

0.03 |

0.02 |

0.02 |

0.3-0.60 |

0.15-0.3 |

79.0-81.0 |

- |

- |

4.8-5.2 |

≤0.2 |

- |

- |

Rest |

- |

|

|

1J87 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

≤0.3 |

78.5-80.5 |

- |

- |

1.6-2.2 |

- |

- |

6.5-7.5 |

Rest |

- |

For more details, pls directly contact us.

Technical Composition and Properties

| Property | Typical Value | Notes |

|---|---|---|

| Nickel (Ni) | 44–46% | Controls expansion coefficient |

| Iron (Fe) | Balance | Provides strength and structure |

| Cobalt (Co) | ≤1% | Improves thermal stability |

| Density | 8.2 g/cm³ | High-density alloy for durability |

| CTE (20–300°C) | 5.2–5.8 × 10⁻⁶/°C | Matches ceramics and glass |

| Electrical Resistivity (20°C) | 0.48 μΩ·m | Stable conductivity |

| Tensile Strength | 520–680 MPa | Maintains mechanical integrity |

| Hardness | 180–220 HB | Balanced for machining and forming |

| Magnetic Transition (Curie Point) | ~420°C | Predictable magnetic behavior |

Application Fields

The High Stability 4J45 Plate is used across several high-precision applications:

-

Semiconductor Packages – Bases and lids for ICs, transistors, and power modules.

-

Optoelectronic Assemblies – Laser diode headers, photodiode housings, and sensor mounts.

-

Aerospace Systems – Used in hermetically sealed electrical connectors and navigation modules.

-

Medical Electronics – Components in imaging and implantable devices requiring biocompatible sealing.

-

Vacuum Devices – Feedthrough plates and electronic tubes that rely on zero-leak sealing.

DLX supports custom dimensions, thickness control (0.05–5 mm), and surface finishes such as bright annealed, oxidized, or nickel-plated, depending on sealing method and downstream processing requirements.

Industry Trend Analysis

The electronics industry is evolving toward higher integration, reliability, and miniaturization, which increases demand for materials with controlled expansion and superior sealing performance. In recent years, three key industry shifts have driven growth for 4J45:

-

Microelectronics and MEMS Packaging – As chip structures become more delicate, even small mismatches in expansion between metal and glass cause seal stress. 4J45’s precise CTE alignment helps maintain integrity under high-temperature bonding.

-

Vacuum and Optoelectronic Systems – With the rise of laser, sensor, and vacuum applications, materials with high purity and stable oxidation characteristics have become essential.

-

Global Reliability Standards – Manufacturers now require materials that meet ISO 9001, SGS, and RoHS/REACH compliance, ensuring export readiness and environmental safety.

At DLX, we’ve adapted to these trends by refining our vacuum melting and annealing technology to deliver consistent thermal and mechanical performance lot after lot.

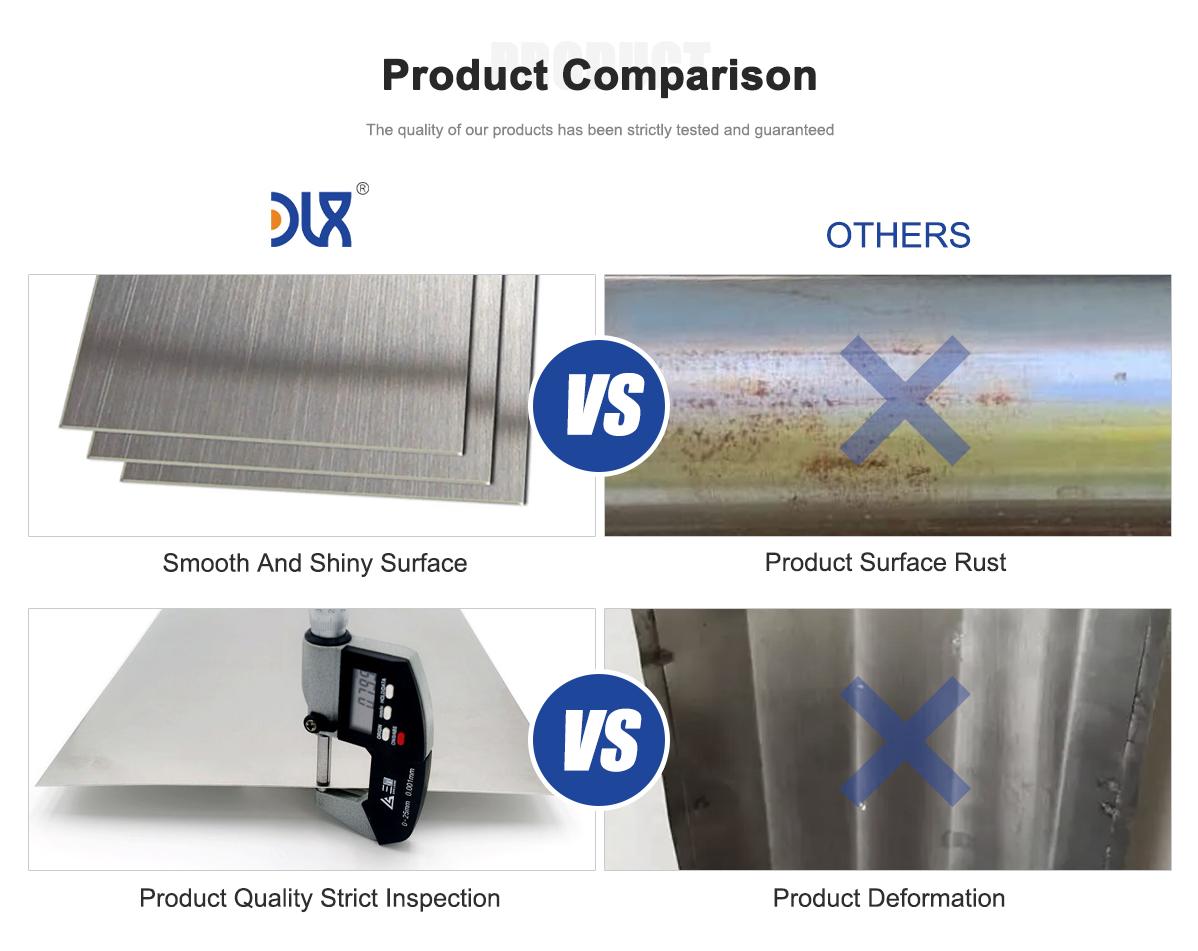

Why DLX 4J45 Stands Out

-

Vacuum Melted, Precision Rolled – Eliminates inclusions and improves grain uniformity, reducing failure risk during sealing.

-

Tight CTE Control – Each batch is tested to ensure CTE deviation stays within ±0.05 × 10⁻⁶/°C.

-

Flatness Guarantee – ≤0.02 mm per 200 mm, crucial for semiconductor sealing lines.

-

Certified Quality – Verified through SGS and TÜV third-party testing for mechanical strength, expansion consistency, and purity.

-

Tailored Engineering Support – DLX engineers work directly with customer teams to optimize brazing temperatures, seal geometry, and plate selection.

-

Batch Traceability – Full melt and process documentation accompany every shipment.

-

Surface Treatment Expertise – We provide clean and oxidation-controlled finishes for superior bonding performance.

These details might seem small, but for manufacturers in high-precision fields, the difference between a good plate and a great one can mean a 10–20% improvement in sealing yield.

Comparison Table — DLX 4J45 vs. Standard Controlled Expansion Plate

| Parameter | DLX 4J45 Plate | General Alloy Plate |

|---|---|---|

| Nickel Control | ±0.15% | ±0.5% |

| Flatness | ≤0.02 mm | ≤0.05 mm |

| CTE Consistency | ±0.05 ×10⁻⁶/°C | ±0.1 ×10⁻⁶/°C |

| Surface Purity | ≤0.002% total impurities | ≤0.01% |

| Thickness Tolerance | ±0.005 mm | ±0.02 mm |

| Certification | SGS / TÜV / ISO | Limited internal QA |

| Oxidation Resistance | Excellent | Moderate |

| Export Documentation | Complete | Partial |

The tighter tolerance and verified thermal behavior of DLX 4J45 make it the preferred choice for precision sealing and semiconductor packaging, where temperature mismatches can’t be tolerated.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What makes DLX 4J45 suitable for precision electronic applications?

Its controlled CTE aligns with ceramics and glass used in electronics, minimizing stress during sealing and operation.

2. What’s the difference between 4J42 and 4J45?

4J45 has slightly higher nickel content and a higher CTE, making it suitable for sealing with glasses or ceramics that expand more than those used with 4J42.

3. How do you ensure surface cleanliness?

Each plate undergoes ultrasonic cleaning and vacuum annealing to remove oxides and contaminants, ensuring ideal bonding conditions.

4. Can 4J45 be used in vacuum environments?

Yes. DLX 4J45 has low outgassing and excellent vacuum compatibility due to its high purity and controlled surface oxidation.

5. What surface finishes are available?

We offer bright annealed, oxidized, and nickel-plated surfaces depending on sealing requirements.

6. How is product consistency verified?

Every production lot undergoes chemical analysis, CTE testing, and dimensional inspection before shipment, with reports traceable to each melt.

7. Is third-party certification available?

Yes. SGS and TÜV have tested and verified DLX 4J45 plates for compliance and performance consistency.

8. Can DLX support small-volume orders or samples?

Absolutely. We supply small quantities for R&D, prototyping, and testing, complete with analytical data and CTE curves.

Expert Experience from DLX

Working with semiconductor packaging and optical component manufacturers has shown us that thermal mismatch failures often originate from subtle inconsistencies in alloy microstructure or surface condition. By refining our vacuum melting and annealing process, we’ve achieved a 25% improvement in dimensional stability and significantly reduced CTE deviation compared to general production-grade alloys.

Our collaboration with third-party test agencies like SGS provides independent confirmation of composition accuracy, microstructural uniformity, and mechanical strength. These reports are shared transparently with customers who need compliance documentation for global supply chains.

DLX’s customers in Europe and Asia have adopted 4J45 plates for hermetic sealing in sensor housings and high-reliability connectors — reporting fewer brazing defects and improved long-term performance under extreme temperature cycles.

By combining real production experience, data-driven control, and customer-focused engineering, DLX continues to provide high-stability controlled expansion materials that meet the evolving standards of the semiconductor and electronics industries.