The 4J36 controlled expansion plate, widely known as Invar 36, is a nickel-iron alloy distinguished for its ultra-low coefficient of thermal expansion (CTE). Its remarkable dimensional stability under temperature variation makes it a staple in precision instruments, aerospace systems, semiconductor packaging, and high-accuracy electronic devices.

At DLX Alloy, we specialize in producing 4J36 plates with consistently optimized microstructure, mechanical strength, and thermal properties, providing reliable performance in applications where even slight dimensional changes can affect system accuracy.

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

1J22 | 0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - | |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - | |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

4J36 is composed of approximately 36% nickel and 64% iron, forming a near-zero expansion alloy. Its CTE is typically around 1.2 × 10⁻⁶ /°C over 20–100°C, significantly lower than most metals. This property, combined with its good mechanical strength, corrosion resistance, and machinability, makes it ideal for components where thermal expansion could compromise precision.

Key material properties include:

Minimal thermal expansion to ensure dimensional stability

Excellent structural integrity and mechanical durability

High processability: can be cut, machined, welded, and formed

Stable magnetic and electrical properties over moderate temperatures

Compatibility with glass and ceramics for sealing applications

DLX Alloy employs vacuum induction melting, precise rolling, and controlled annealing, resulting in 4J36 plates with uniform composition, low internal stress, and high surface quality, ideal for precision assemblies and aerospace applications.

Applications

The 4J36 controlled expansion plate is widely applied wherever thermal stability and dimensional precision are critical:

Precision instruments: gyroscopes, measurement devices, and optical mounts

Aerospace systems: guidance frames, satellite components, and structural supports

Semiconductor packaging: substrates and frames with minimal thermal drift

Glass-to-metal and ceramic sealing: vacuum tubes, sensors, and hermetic packages

Scientific equipment: telescopes, microscopes, and laser systems

Control systems: actuators and precision relays requiring high dimensional accuracy

DLX Alloy customizes 4J36 plates for exact thickness, size, and surface finish, ensuring optimal integration into high-precision systems.

As industries like aerospace, electronics, and instrumentation evolve, the demand for materials with ultra-low thermal expansion has increased. High-precision systems require metals that maintain dimensional stability under fluctuating environmental conditions.

Trends impacting 4J36 use include:

Miniaturization of electronic devices: requires materials that maintain tight tolerances despite temperature swings

Advanced aerospace systems: satellite and aviation components demand ultra-stable structures

High-precision scientific instruments: optical systems and sensors require negligible thermal deformation

Semiconductor advancement: substrates and packages need materials with matched thermal expansion to prevent stress and defects

DLX Alloy continues to innovate in 4J36 production to meet these trends, optimizing annealing processes, rolling parameters, and microstructure control to deliver plates that consistently meet stringent performance standards.

| Property / Alloy | 4J36 | 4J42 | 4J33 | Kovar (4J29) |

|---|---|---|---|---|

| Nickel Content (%) | 36 | 42 | 33 | 29 |

| CTE (20–100°C, ×10⁻⁶/°C) | 1.2 | 2.0 | 1.5 | 5.0 |

| Density (g/cm³) | 8.1 | 8.1 | 8.0 | 8.2 |

| Yield Strength (MPa) | 250–350 | 300–400 | 220–320 | 250–350 |

| Thermal Stability | Excellent | Very Good | Good | Moderate |

| Corrosion Resistance | Good | Good | Good | Moderate |

| Typical Applications | Precision instruments, aerospace | Glass-to-metal seals | Low-expansion frames | Semiconductor packaging |

| Processability | Excellent | Good | Good | Moderate |

From this comparison, 4J36 provides the lowest thermal expansion, making it the preferred alloy for aerospace and high-precision instrumentation applications.

Why Choose DLX Alloy

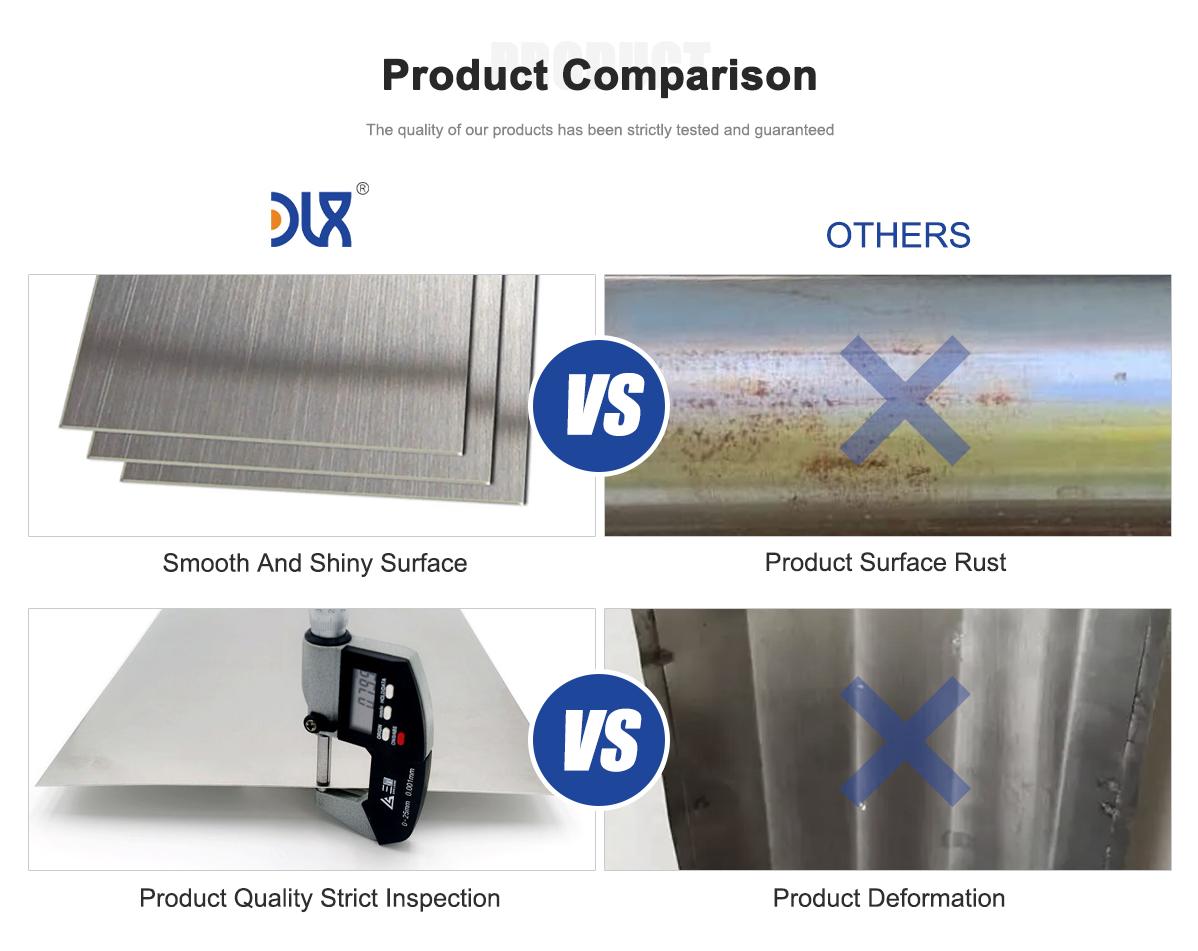

DLX Alloy combines metallurgical expertise, precise engineering, and rigorous quality control to produce 4J36 plates that meet demanding standards.

Advantages of DLX 4J36 plates include:

Vacuum induction melting for chemical uniformity and minimal impurities

Precision rolling and annealing to optimize microstructure and reduce residual stress

Strict dimensional tolerances for assembly precision

Custom surface finishes for critical applications

Comprehensive testing for CTE, mechanical, and chemical properties

DLX Alloy ensures that each plate integrates seamlessly into precision instruments and aerospace systems, delivering reliable performance and longevity

DLX Alloy leverages advanced equipment and production techniques:

Vacuum induction furnaces for homogeneous alloy melting

High-precision rolling mills for uniform thickness and flatness

Controlled annealing ovens to relieve internal stress and optimize thermal properties

Every batch undergoes rigorous inspection:

Coefficient of Thermal Expansion testing

Mechanical strength evaluation

Surface flatness and roughness assessment

Chemical composition verification

This comprehensive process guarantees that DLX 4J36 plates meet the highest precision standards for aerospace and instrumentation applications.

Sustainability and Market Outlook

With increasing emphasis on precision, efficiency, and reliability, the use of 4J36 low-expansion alloys continues to grow. Applications in aerospace, electronics, and high-precision instrumentation demand materials that maintain dimensional stability under thermal and mechanical stress, ensuring long-term reliability.

DLX Alloy integrates sustainable practices by minimizing production waste, recycling metal scraps, and optimizing energy use during melting and annealing. As the market for precision electronics and aerospace systems expands, DLX is positioned to provide high-performance, environmentally responsible 4J36 plates.

4J36 Invar Alloy Plate is essential for high-precision instrumentation, aerospace components, and semiconductor systems requiring minimal thermal expansion. Its combination of low CTE, mechanical strength, and processability makes it a versatile and reliable choice.

DLX Alloy ensures every 4J36 plate delivers consistent performance, tight tolerances, and long-term stability, making it a preferred material for critical applications across advanced technology sectors.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the composition of 4J36?

It contains approximately 36% nickel and 64% iron, optimized for minimal thermal expansion.

2. What is the main benefit of 4J36 plates?

Ultra-low thermal expansion ensures dimensional stability under temperature variation.

3. Which industries primarily use 4J36?

Aerospace, precision instruments, semiconductor packaging, and scientific equipment.

4. How does 4J36 compare to 4J42?

4J36 has a lower CTE, providing superior dimensional stability for highly precise applications.

5. Can DLX provide custom plate sizes and thicknesses?

Yes, DLX offers customized dimensions, thickness, and surface treatments.

6. Is 4J36 compatible with glass and ceramics?

Yes, it is widely used for glass-to-metal and ceramic sealing applications.

7. What heat treatment improves 4J36 properties?

Controlled annealing under vacuum or inert gas enhances thermal stability and relieves internal stress.

8. Does DLX Alloy provide testing reports?

Yes, every batch comes with CTE, mechanical, and chemical analysis reports.