The 4J47 nickel-iron alloy plate is a high-performance soft magnetic material widely used in magnetic shielding, precision sensors, transformers, and electromagnetic control systems. Known for its excellent magnetic permeability, low coercivity, and strong shielding capability, this alloy plays a vital role in protecting sensitive equipment from electromagnetic interference (EMI). At DLX Alloy, we focus on delivering stable, high-purity 4J47 materials that meet the demanding requirements of global industries, from electronics to aerospace.

4J47 is a nickel-iron alloy containing approximately 47% nickel, making it part of the high-permeability soft magnetic alloy family. It exhibits very high initial and maximum permeability, along with low magnetic loss, making it ideal for environments where magnetic field control and EMI suppression are critical.

At DLX Alloy, we produce 4J47 plates through vacuum induction melting, precision cold rolling, and hydrogen atmosphere annealing, ensuring a uniform crystal structure and stable magnetic performance. Our advanced heat treatment technology enhances the alloy’s ability to maintain high permeability even after mechanical processing, allowing for superior consistency in practical applications.

Alloy Composition Table

Alloy Grades | C | S | P | Mn | Si | Ni | Cr | Co | Mo | Cu | Al | Nb | Fe | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1J06 | 0.04 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 5.5-6.5 | - | Rest | - |

1J12 | 0.03 | 0.015 | 0.015 | ≤0.10 | ≤0.15 | - | - | - | - | - | 11.6-12.4 | - | Rest | - |

1J17 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | - | 15.5-16.5 | - | - | - | - | - | Rest | - |

1J18 | 0.03 | 0.02 | 0.02 | 0.3-0.7 | ≤0.15 | 0.5-0.7 | 17-18.5 | - | - | - | - | - | Rest | Ti: 0.3-0.7 |

0.04 | 0.02 | 0.02 | ≤0.3 | ≤0.3 | ≤0.5 | - | 49-51 | - | ≤0.2 | - | - | Rest | V: 0.8-1.8 | |

1J30 | 0.04 | 0.02 | 0.02 | ≤0.40 | ≤0.30 | 29.5-30.5 | - | - | - | - | - | - | Rest | - |

1J36 | 0.03 | 0.02 | 0.02 | ≤0.60 | ≤0.20 | 35.0-37.0 | - | - | - | - | - | - | Rest | - |

1J38 | 0.03 | 0.05 | 0.02 | 0.3-0.6 | 0.15-0.3 | 37.5-38.5 | 12.5-13.5 | - | - | - | - | - | Rest | - |

1J46 | 0.03 | 0.02 | 0.02 | 0.6-1.1 | 0.15-0.3 | 45.0-46.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J50 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J51 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 49-50.5 | - | - | - | ≤0.2 | - | - | Rest | - |

1J54 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 1.1-1.4 | 49.5-51 | 3.8-4.2 | - | - | ≤0.2 | - | - | Rest | - |

1J76 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.0-76.5 | 1.8-2.2 | - | - | 4.8-5.2 | - | - | Rest | - |

1J77 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | 0.15-0.3 | 75.5-78 | - | - | 3.9-4.5 | 4.8-6.0 | - | - | Rest | - |

1J79 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 0.3-0.5 | 78.5-80.0 | - | - | 3.8-4.1 | ≤0.2 | - | - | Rest | - |

1J80 | 0.03 | 0.02 | 0.02 | 0.6-1.10 | 1.1-1.5 | 79.0-81.5 | 2.6-3.0 | - | - | ≤0.2 | - | - | Rest | - |

1J85 | 0.03 | 0.02 | 0.02 | 0.3-0.60 | 0.15-0.3 | 79.0-81.0 | - | - | 4.8-5.2 | ≤0.2 | - | - | Rest | - |

1J87 | 0.03 | 0.02 | 0.02 | 0.3-0.6 | ≤0.3 | 78.5-80.5 | - | - | 1.6-2.2 | - | - | 6.5-7.5 | Rest | - |

For more details, pls directly contact us.

High initial and maximum magnetic permeability – enhances sensitivity and reduces magnetic noise.

Low coercive force – minimizes energy loss during magnetization and demagnetization.

Excellent magnetic shielding performance – effectively isolates weak magnetic fields.

Stable performance under thermal stress – retains properties even under moderate temperatures.

Good mechanical strength and processability – suitable for forming, welding, and shaping into complex parts.

Superior corrosion resistance – performs reliably in humid or industrial environments.

Applications

The 4J47 nickel-iron plate is widely used in high-precision industries that depend on magnetic stability and interference control. Typical applications include:

Magnetic Shielding Systems – Used in medical imaging, laboratories, and electronics to block external magnetic fields.

Precision Instruments – Ensures stable readings in measuring and navigation devices.

Sensors and Detectors – Improves sensitivity by minimizing interference.

Transformers and Inductors – Reduces core losses and enhances energy efficiency.

Magnetic Amplifiers – Provides linear magnetic response for control applications.

Electronic Enclosures – Forms shielding layers for high-accuracy circuits.

Aerospace and Defense Equipment – Protects critical systems from stray magnetic fields.

At DLX Alloy, we customize plate thickness, surface finish, and heat treatment parameters to fit the precise shielding and permeability requirements of different industries.

| Property | 4J47 (DLX Alloy) | 4J50 | 4J79 | 4J36 (Invar) |

|---|---|---|---|---|

| Nickel Content (%) | 47 ± 1 | 50 ± 1 | 79 ± 1 | 36 ± 1 |

| Density (g/cm³) | 8.25 | 8.25 | 8.7 | 8.1 |

| Saturation Flux Density (T) | 0.9 | 0.8 | 0.8 | 0.6 |

| Maximum Permeability (μmax) | ≥ 70,000 | ≥ 80,000 | ≥ 100,000 | ≤ 10,000 |

| Coercive Force (A/m) | ≤ 6 | ≤ 5 | ≤ 4 | ≤ 10 |

| Curie Temperature (°C) | ~480 | ~400 | ~450 | ~230 |

| Magnetic Shielding Effect | Excellent | Excellent | Superior | Moderate |

| Machinability | Good | Fair | Fair | Good |

| Corrosion Resistance | Excellent | Excellent | Excellent | Good |

From the table, 4J47 demonstrates an excellent balance of high permeability, stable saturation induction, and good mechanical strength, making it the ideal choice for magnetic shielding applications where both performance and durability are required.

Industry Analysis

In today’s world of high-frequency electronics and precision control systems, managing electromagnetic interference has become increasingly important. As devices become smaller and more sensitive, the need for reliable magnetic shielding materials has risen dramatically.

4J47 alloy has become a key solution due to its high permeability and ability to stabilize low-intensity magnetic fields. Industries like medical imaging, aerospace, and instrumentation rely heavily on this alloy to ensure performance stability and data accuracy. For example, in MRI rooms, 4J47 plates are used to shield external magnetic interference, ensuring the clarity of imaging results.

At DLX Alloy, we keep pace with industry trends by focusing on precision production, material consistency, and performance optimization. Our 4J47 alloy products align with modern needs for miniaturization, high-frequency response, and environmental reliability, supporting the evolution of advanced magnetic shielding technologies worldwide.

DLX Alloy Advantage

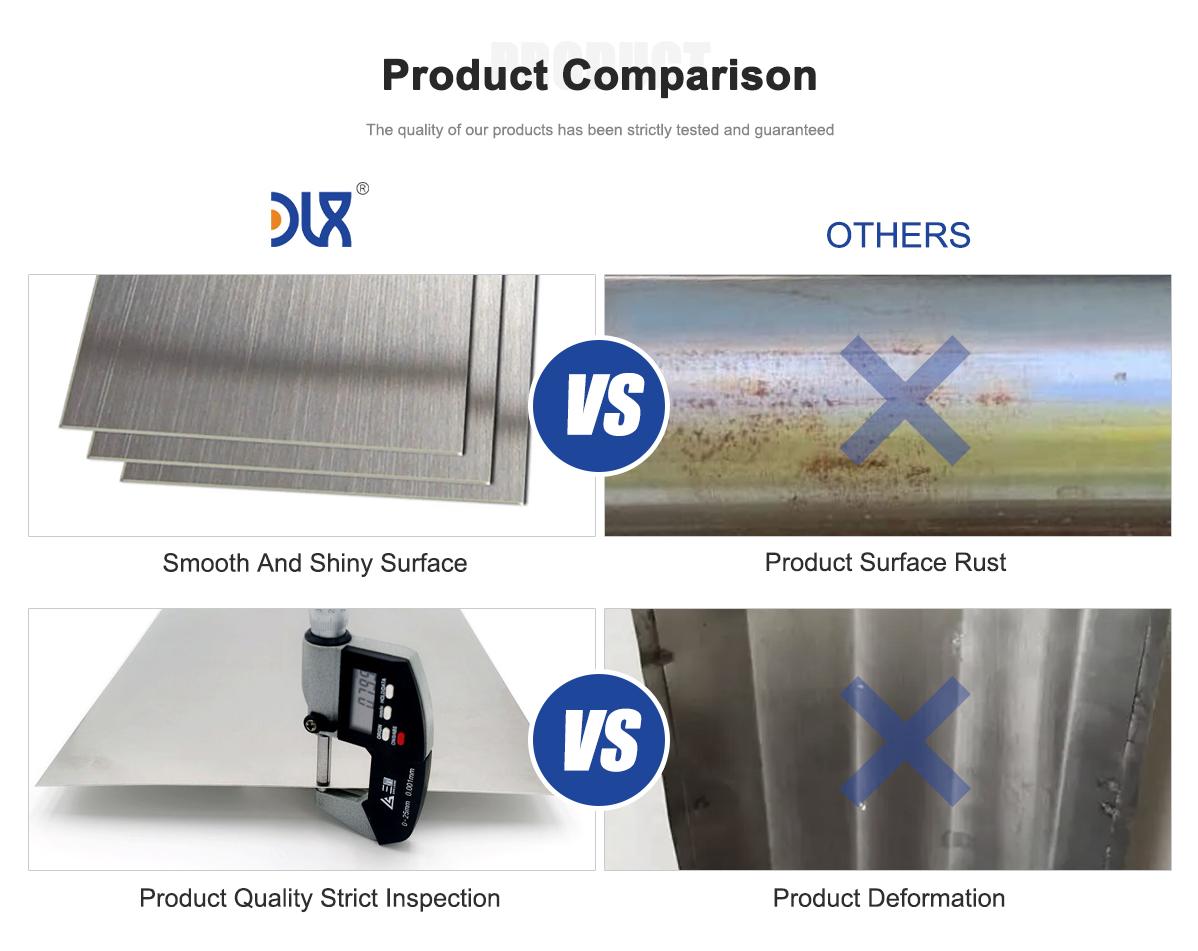

DLX Alloy has earned a strong reputation as a trusted supplier of soft magnetic materials due to our technological innovation, process control, and customer-focused production. Here’s what sets our 4J47 plates apart:

Vacuum Melting Precision – Ensures high purity and uniform element distribution.

Advanced Rolling and Annealing – Hydrogen-protected annealing achieves optimal permeability and minimal stress.

Custom Processing – Available in a variety of thicknesses (0.1 mm to 10 mm) with tailored surface finishes.

Tight Dimensional Tolerance – Precision-controlled flatness and thickness uniformity.

Strict Quality Inspection – Magnetic, mechanical, and chemical tests ensure reliability for critical systems.

Technical Expertise – DLX provides engineering support for material selection and application design.

Global Supply Capability – Stable export performance to Asia, Europe, and North America.

Sustainable Production – Low-emission, eco-friendly manufacturing processes that meet global standards.

These capabilities allow DLX Alloy to deliver high-performance magnetic materials that help manufacturers build more accurate, efficient, and durable systems for modern industrial and scientific applications.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is 4J47 made of?

It’s a nickel-iron alloy with approximately 47% nickel, providing excellent magnetic permeability and stability.

2. Why is 4J47 suitable for magnetic shielding?

Its high permeability allows it to effectively absorb and redirect magnetic flux, reducing external field interference.

3. What’s the difference between 4J47 and 4J79?

4J79 has higher permeability but lower saturation induction, while 4J47 provides a better balance between strength and shielding performance.

4. What industries typically use 4J47?

It’s used in electronics, aerospace, medical, and scientific instruments for magnetic shielding and field control.

5. Can DLX Alloy customize the plate thickness and dimensions?

Yes, we provide tailor-made sizes and finishes based on customer specifications.

6. What is the Curie temperature of 4J47?

The Curie point is approximately 480°C, allowing stable magnetic performance under moderate heat.

7. How is the magnetic shielding efficiency tested?

We use precision magnetic field analyzers to verify permeability, shielding factor, and hysteresis characteristics.

8. Why choose DLX Alloy’s 4J47 plate?

Because DLX provides consistent quality, advanced annealing treatment, and professional technical support for industrial and electronic applications.

Conclusion

The 4J47 Nickel-Iron Alloy Plate is a cornerstone material for magnetic shielding and field-sensitive equipment, combining excellent magnetic permeability, low coercive force, and reliable mechanical strength. As technology advances toward higher precision and lower interference, materials like 4J47 will continue to play an essential role in the development of sensors, instruments, and electromagnetic systems.

At DLX Alloy, our focus on precision manufacturing, quality consistency, and technical innovation ensures that every 4J47 plate performs beyond expectations. Whether used in medical systems, aerospace electronics, or precision instruments, DLX’s 4J47 alloy guarantees the shielding performance and stability that engineers and manufacturers depend on.