Our 1J22 Iron-Cobalt plate is a high-performance Soft Magnetic Alloy engineered for applications requiring exceptional magnetic saturation and robust mechanical properties. With a composition of roughly 49% cobalt, 2% vanadium, and iron, this alloy boasts a magnetic saturation of up to 24 kilogauss, making it a powerhouse for electromagnetic devices. It’s the go-to material for industries needing compact, high-efficiency components like motors, transformers, and magnetrons, delivering reliability and precision in every application.

The soft magnetic materials market is booming, fueled by the rise of electric vehicles (EVs), renewable energy, and advanced electronics. As industries push for smaller, more efficient systems, alloys like 1J22 Iron-Cobalt are in high demand for their ability to maximize power density. Market reports project steady growth in this sector through 2030, with automotive, aerospace, and defense leading the way. Challenges like material cost and processing complexity are being tackled through innovations in alloy production, where we excel with advanced techniques like vacuum melting and precision rolling to ensure top quality.

Our 1J22 Iron-Cobalt plate is versatile and shines in demanding applications:

-

Electromagnetic Motors: Its high saturation enables smaller, more powerful motors for EVs and industrial systems.

-

Transformers: Low core losses and high permeability make it ideal for efficient power distribution.

-

Magnetrons: Perfect for radar and microwave systems, offering stable magnetic performance at high temperatures.

-

Aerospace Systems: Used in actuators and magnetic bearings, its strength and thermal stability are unmatched.

-

Sensors and Relays: High sensitivity and low coercive force enhance precision in electromagnetic sensors.

Alloy Composition Table

|

Alloy Grades |

C |

S |

P |

Mn |

Si |

Ni |

Cr |

Co |

Mo |

Cu |

Al |

Nb |

Fe |

Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1J06 |

0.04 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

5.5-6.5 |

- |

Rest |

- |

|

1J12 |

0.03 |

0.015 |

0.015 |

≤0.10 |

≤0.15 |

- |

- |

- |

- |

- |

11.6-12.4 |

- |

Rest |

- |

|

1J17 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

- |

15.5-16.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J18 |

0.03 |

0.02 |

0.02 |

0.3-0.7 |

≤0.15 |

0.5-0.7 |

17-18.5 |

- |

- |

- |

- |

- |

Rest |

Ti: 0.3-0.7 |

|

1J22 |

0.04 |

0.02 |

0.02 |

≤0.3 |

≤0.3 |

≤0.5 |

- |

49-51 |

- |

≤0.2 |

- |

- |

Rest |

V: 0.8-1.8 |

|

1J30 |

0.04 |

0.02 |

0.02 |

≤0.40 |

≤0.30 |

29.5-30.5 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J36 |

0.03 |

0.02 |

0.02 |

≤0.60 |

≤0.20 |

35.0-37.0 |

- |

- |

- |

- |

- |

- |

Rest |

- |

|

1J38 |

0.03 |

0.05 |

0.02 |

0.3-0.6 |

0.15-0.3 |

37.5-38.5 |

12.5-13.5 |

- |

- |

- |

- |

- |

Rest |

- |

|

1J46 |

0.03 |

0.02 |

0.02 |

0.6-1.1 |

0.15-0.3 |

45.0-46.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J50 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J51 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

49-50.5 |

- |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J54 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

1.1-1.4 |

49.5-51 |

3.8-4.2 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J76 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.0-76.5 |

1.8-2.2 |

- |

- |

4.8-5.2 |

- |

- |

Rest |

- |

|

1J77 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

0.15-0.3 |

75.5-78 |

- |

- |

3.9-4.5 |

4.8-6.0 |

- |

- |

Rest |

- |

|

1J79 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

0.3-0.5 |

78.5-80.0 |

- |

- |

3.8-4.1 |

≤0.2 |

- |

- |

Rest |

- |

|

1J80 |

0.03 |

0.02 |

0.02 |

0.6-1.10 |

1.1-1.5 |

79.0-81.5 |

2.6-3.0 |

- |

- |

≤0.2 |

- |

- |

Rest |

- |

|

1J85 |

0.03 |

0.02 |

0.02 |

0.3-0.60 |

0.15-0.3 |

79.0-81.0 |

- |

- |

4.8-5.2 |

≤0.2 |

- |

- |

Rest |

- |

|

1J87 |

0.03 |

0.02 |

0.02 |

0.3-0.6 |

≤0.3 |

78.5-80.5 |

- |

- |

1.6-2.2 |

- |

- |

6.5-7.5 |

Rest |

- |

For more details, pls directly contact us.

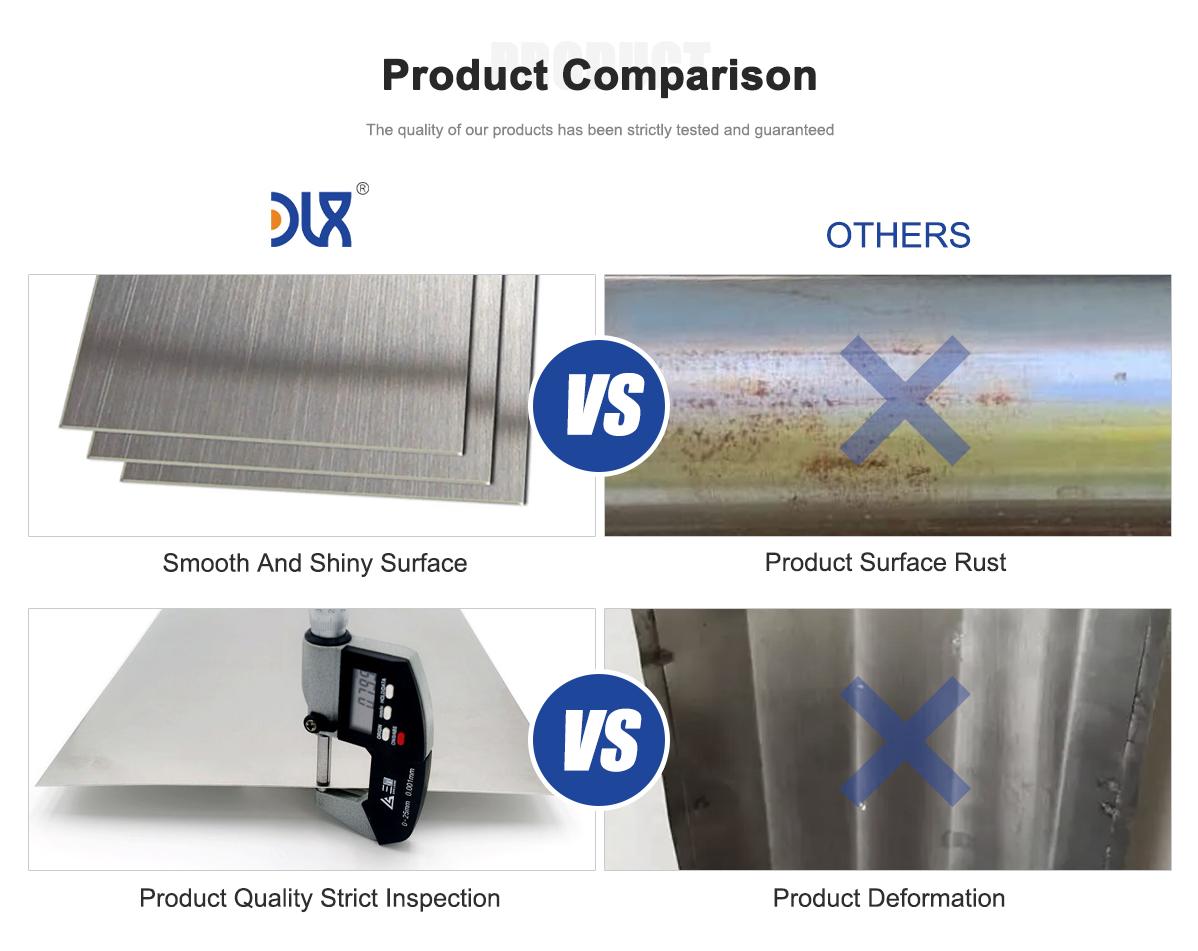

Our 1J22 Iron-Cobalt plate sets the standard in the industry. Using state-of-the-art vacuum induction melting and proprietary heat treatment, we achieve superior magnetic and mechanical properties. We offer fully customizable plate dimensions, ensuring a perfect fit for your project, with lead times as short as 15 days. Our ISO 9001-certified quality control guarantees consistency, and our in-house R&D team optimizes the alloy for better workability and corrosion resistance. Plus, we provide free samples (shipping costs apply) and unmatched customer support to get your project moving fast.

Comparison Table

|

Parameter |

Our 1J22 Iron-Cobalt Plate |

Competitor Alloy |

|---|---|---|

|

Magnetic Saturation |

24 kilogauss |

22-23 kilogauss |

|

Coercive Force |

0.4 Oe |

0.5-0.8 Oe |

|

Curie Temperature |

980°C |

900-950°C |

|

Yield Strength |

365-435 MPa |

320-400 MPa |

|

Core Loss |

Low (AC-optimized) |

Moderate |

|

Processing |

Vacuum melting, custom sizes |

Standard processing |

|

Lead Time |

15-20 days |

25-35 days |

|

Quality Certification |

ISO 9001 |

Varies |

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is 1J22 Iron-Cobalt plate made of?

It’s an iron-cobalt-vanadium alloy with ~49% cobalt, 2% vanadium, and iron, optimized for high magnetic saturation. -

What are the main properties of 1J22 Iron-Cobalt?

It features 24 kilogauss magnetic saturation, 0.4 Oe coercive force, a 980°C Curie temperature, and high mechanical strength. -

Which industries use 1J22 Iron-Cobalt plates?

Automotive, aerospace, electronics, defense, and energy sectors rely on it for motors, transformers, and magnetrons. -

Can it handle high-temperature environments?

Absolutely, its high Curie point ensures magnetic stability at elevated temperatures. -

What forms do you offer for 1J22 Iron-Cobalt?

We provide plates, sheets, strips, and custom shapes, tailored to your specifications. -

How does it improve electromagnetic performance?

Its high saturation and low losses enable compact, high-efficiency designs for motors and transformers. -

Is it suitable for high-frequency applications?

With a resistivity of 0.27 μΩ·m, it’s best for low- to medium-frequency electromagnetic systems. -

How can I get a sample?

Reach out for a free sample (buyer pays shipping), with delivery typically within 15 days of payment.

Why Choose Our 1J22 Iron-Cobalt Plate?

Our 1J22 Iron-Cobalt plate is built for performance, combining top-tier magnetic properties with the durability needed for cutting-edge applications. With decades of expertise, we’ve perfected our production process to deliver a cost-effective, high-quality product. Whether you’re designing next-gen motors or precision sensors, our plates give you the edge in efficiency and reliability. Contact us today to see how our 1J22 Iron-Cobalt plate can elevate your electromagnetic projects!